Which industries can benefit from CO₂ recovery technology?

•

Which industries can benefit from CO₂ recovery technology?

Your factory vents CO₂ as a waste product, costing you money in carbon taxes and lost opportunities. This isn't just an environmental problem; it's a direct hit to your operational efficiency and bottom line.

Industries that either produce a concentrated CO₂ stream or consume large volumes of CO₂ benefit the most. Key sectors include breweries, ethanol plants, chemical and fertilizer production, power generation, and food processing. The primary benefits are reduced costs, new revenue streams, and a smaller carbon footprint.

I've worked with engineers across many sectors, and while their products are different, their CO₂ challenges are often similar. They have a gas stream that's considered waste but is full of potential value. It's easy to talk about this technology in broad terms, but the real benefits become clear when you look at how specific industries apply it to their unique processes. Let's explore some of the most successful applications I've seen firsthand.

How is CO₂ recovery applied in breweries and beverage production?

Beverage plants pay for tanker loads of CO₂ for carbonation, while simultaneously venting high-purity CO₂ from their fermentation tanks. You are buying a product that you are also throwing away for free.

In breweries, CO₂ recovery systems capture the pure CO₂ from fermentation tanks, purify it to beverage-grade standards (over 99.9%), and reuse it on-site for carbonating products and purging equipment. This closes the loop and eliminates the need to purchase external CO₂.

The brewing industry is one of the clearest examples of a perfect business case for CO₂ recovery. The fermentation process naturally produces a stream of CO₂ that is already more than 99% pure. This makes the capture and purification process incredibly efficient and cost-effective. I've seen brewery clients achieve a return on their investment in as little as two years.

The process is straightforward. We collect the CO₂ from the fermenter headspace, pass it through a foam trap and then a multi-stage system to compress, dry, and filter it. The purification train, which uses activated carbon filters, is crucial for removing any trace aroma compounds that could affect the final beverage's taste. The end product is a consistent, reliable supply of high-purity liquid CO₂, ready to be used for carbonating the beer. This creates a self-sufficient and highly profitable circular economy within the plant's own walls.

| Parameter | Before CO₂ Recovery | After CO₂ Recovery |

|---|---|---|

| CO₂ Source | Purchased from external supplier | Captured from on-site fermentation |

| Fermentation Gas | Vented to atmosphere (waste) | Captured as a valuable asset |

| Cost Center | High, volatile CO₂ purchasing costs | Low, stable operational energy cost |

| Supply Chain | Dependent on external deliveries | Independent and self-sufficient |

Can chemical or fertilizer plants reuse recovered CO₂ effectively?

Chemical processes, like manufacturing ammonia or hydrogen, generate massive amounts of CO₂ as an unavoidable byproduct. Venting this is both a huge emission source and a wasted chemical feedstock.

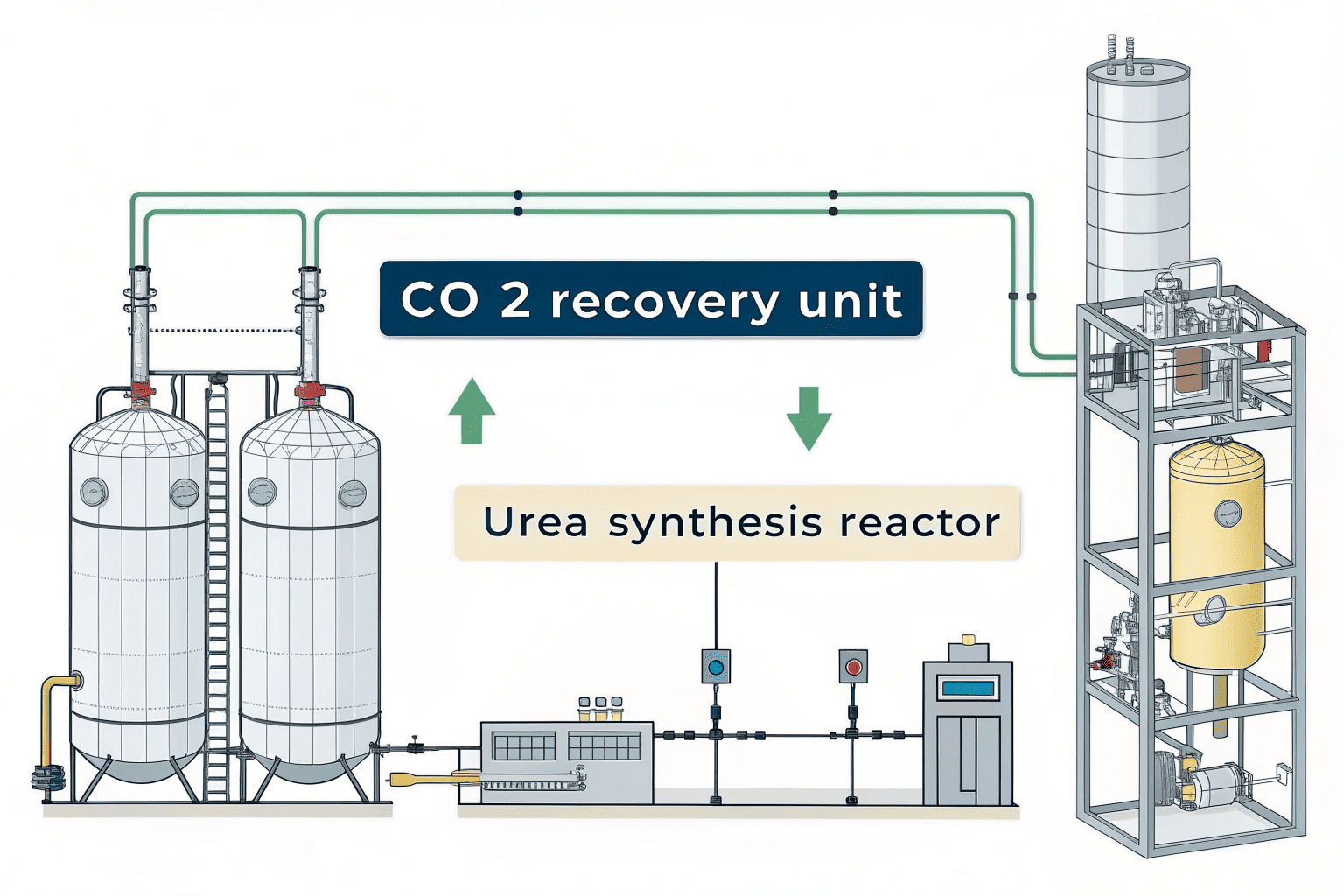

Yes, chemical and fertilizer plants are ideal candidates for CO₂ recovery. The recovered CO₂ is a critical raw material. For instance, ammonia plants capture CO₂ and combine it with ammonia to produce urea fertilizer, a high-value commodity.

In many industries, we're turning waste into a usable product. But in the chemical industry, the recovered CO₂ is often a primary ingredient. I worked on a project for an ammonia plant where the business case wasn't about saving money on CO₂ purchases, but about increasing their production of a completely different product: urea fertilizer. The CO₂ recovery unit isn't just an add-on; it's an integrated and essential part of their core process.

The chemistry is a perfect example of industrial symbiosis. The synthesis of urea requires two main inputs: ammonia (NH₃) and carbon dioxide (CO₂). By capturing the CO₂ byproduct from their hydrogen production process (a necessary step for making ammonia), they have the exact feedstock they need. The recovered CO₂ is piped directly to a synthesis reactor. This transforms a major emission source into a primary revenue driver, dramatically improving the plant's overall efficiency and environmental performance.

| Process | Inputs | Outputs |

|---|---|---|

| Ammonia Plant | Natural Gas, Air, Steam | Ammonia (NH₃) + CO₂ byproduct |

| CO₂ Recovery | Raw CO₂ | Purified CO₂ feedstock |

| Urea Synthesis | Purified CO₂ + Ammonia (NH₃) | Urea Fertilizer (CO(NH₂)₂) + Water |

What other industries are investing in CO₂ recycling systems?

You might not be a brewery or a large chemical plant, but you still have CO₂ emissions. You might be wondering if this technology can apply to your industry and help you become more sustainable.

Beyond the obvious, industries like power generation, cement production, biogas upgrading, and even indoor agriculture are investing in CO₂ systems. They use it to either lower their carbon footprint or to use the CO₂ as a key input for their process, like boosting plant growth.

The application of CO₂ recovery is expanding rapidly as more industries realize its potential. Some of the most exciting projects I've been involved with recently are in these emerging sectors. For example, natural gas power plants are a huge source of emissions. We are helping them capture CO₂ from their flue gas. While the concentration is lower (8-12%), the sheer volume makes it an important target. The captured CO₂ can then be sold for Enhanced Oil Recovery (EOR) or sequestered underground.

Another fascinating area is biogas. When organic waste decomposes in a landfill or digester, it produces biogas (a mix of methane and CO₂). A CO₂ recovery system separates these two gases. The result is purified methane (renewable natural gas) that can be injected into the grid, and a stream of pure CO₂, which can be sold or used in nearby greenhouses to accelerate plant growth. This turns a waste management problem into a dual-revenue-stream solution. These diverse applications show that nearly any industry with a CO₂ stream can find a way to create value from it.

Conclusion

From breweries creating a closed loop to chemical plants using it as feedstock, CO₂ recovery offers major benefits. This flexible technology helps diverse industries cut costs, create revenue, and improve sustainability.

You may also be interested in:

Why is CO₂ recovery technology gaining popularity worldwide?

Why is CO₂ recovery technology gaining popularity worldwide? You see headlines about carbon capture everywhere. But you wonder if it's

Read more

How is a CO₂ recovery system designed to fit different industries?

How is a CO₂ recovery system designed to fit different industries? You're under pressure to implement a CO₂ recovery solution.

Read more

How energy-efficient are today’s CO₂ recovery technologies?

How energy-efficient are today’s CO₂ recovery technologies? You want to recover CO₂, but you fear that high electricity bills will

Read more