What should factories know before installing a CO₂ recovery system?

•

What should factories know before installing a CO₂ recovery system?

You’re ready to save money by capturing your own CO₂. But the thought of a complex installation project with unknown requirements and potential disruptions is holding your team back.

Before installing, factories should assess installation timelines, required utilities like power and water, space for the equipment, and how the system will integrate with their existing production lines. Proper planning in these key areas is crucial for a smooth and successful project.

I've been on countless installation sites, and I know that a successful project is all about good planning. It’s not just about the equipment itself; it’s about how it fits into your world. A great piece of machinery is useless if it doesn't integrate smoothly with your existing operations. We treat every installation as a partnership, making sure every detail is covered before the first wrench is turned. Let’s walk through the key questions you need to answer for a seamless and successful installation.

How long does it take to install a standard CO₂ recovery unit?

You need to plan your production schedule around the installation. A long, unpredictable timeline can cause major disruptions and delays, costing you both time and money.

A typical on-site installation, from equipment delivery to full commissioning, takes between 2 to 4 weeks. However, the total project timeline, including planning, manufacturing, and site preparation, is usually in the range of 3 to 6 months.

The question I get most often is about downtime. Plant managers need to know exactly how long their operations might be affected. The good news is that most of the work happens before the equipment even arrives at your door. The total project is a multi-stage process. We start with detailed planning and design, which can take a month. Then, while we are manufacturing your custom FTL Machine unit at our facility, your team can prepare the site. This phase is the longest, but it doesn't interrupt your production. The actual on-site work is quite fast. Once the skids are delivered, my team comes in for the mechanical and electrical hookup, followed by commissioning. Commissioning is where we start the system, fine-tune the performance, and train your operators. This hands-on part is usually wrapped up in under a month.

Understanding the Full Project Timeline

A typical project is broken down into four distinct phases.

| Phase | Key Activities | Typical Duration | Impact on Your Production |

|---|---|---|---|

| 1. Planning & Engineering | Site assessment, P&ID finalization, layout approval | 4-6 Weeks | None |

| 2. Manufacturing & Delivery | FTL builds the system; you prepare the concrete pad & utilities | 8-16 Weeks | None |

| 3. On-Site Installation | Equipment placement, piping and electrical connections | 2-3 Weeks | Minimal |

| 4. Commissioning & Training | System startup, performance testing, operator training | 1-2 Weeks | Low (scheduled tie-ins) |

This phased approach ensures that production disruptions are kept to an absolute minimum. The most critical integration points, like tying into the main gas line, are scheduled for planned maintenance shutdowns whenever possible to avoid any impact on your output.

What infrastructure or utilities are needed to run the system?

You need to know what you must provide. A surprise requirement for a new high-voltage line or a larger water pipe can delay a project and wreck a budget.

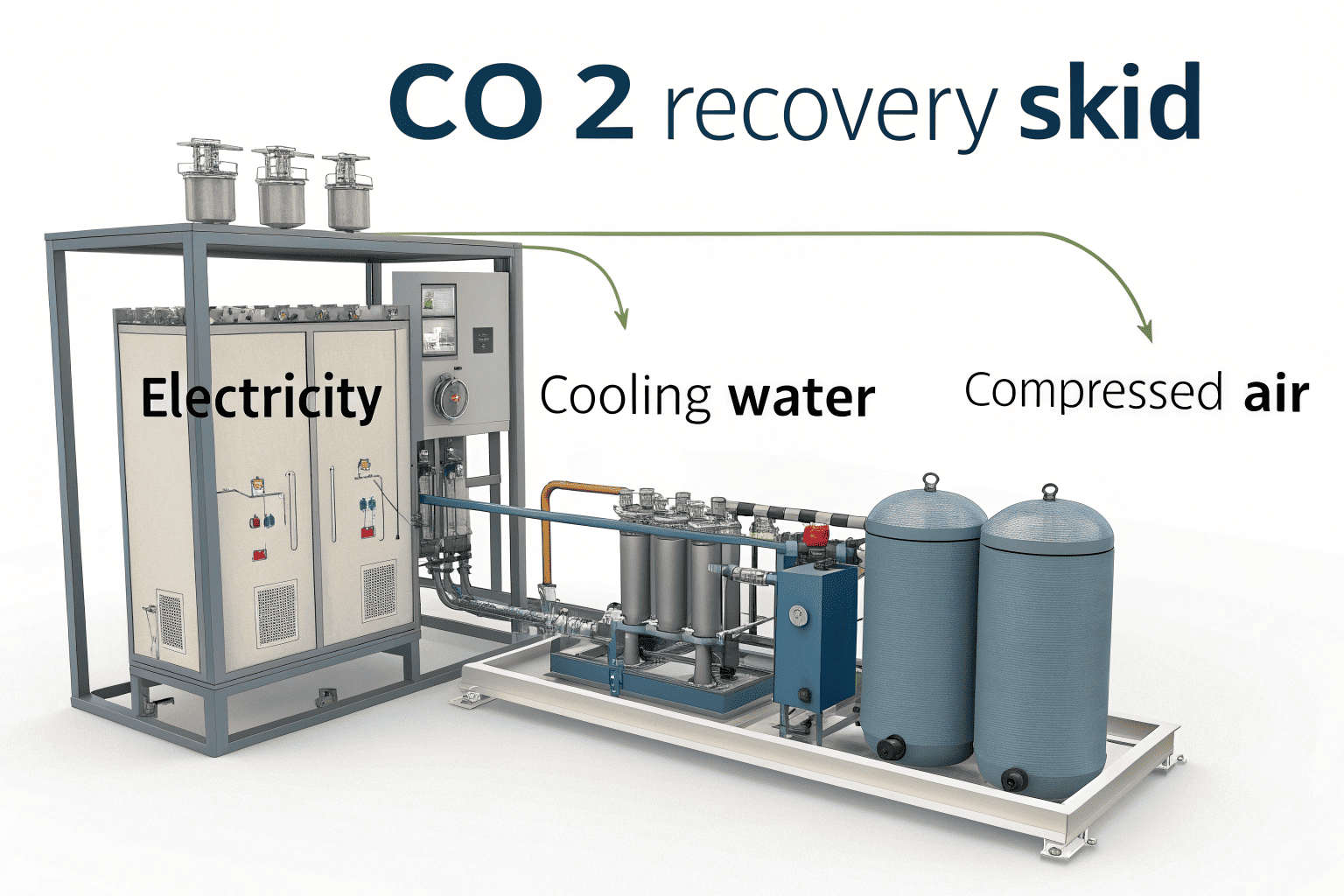

The essential utilities are a stable electrical power supply, a cooling water source, and a supply of compressed air. You also need a dedicated concrete pad with proper drainage to house the equipment skid.

Before we finalize any project, we create a detailed utility checklist. This document is our foundation for a smooth installation. The single biggest requirement is electrical power. The CO₂ compressor is a large motor, so it needs a dedicated, high-voltage connection. The second key utility is cooling water. The compression process generates a lot of heat, which we need to remove efficiently. This is usually done with a cooling tower or a chilled water loop. We'll specify the required flow rate and temperature for our heat exchangers. Lastly, the system’s pneumatic valves run on standard plant compressed air. Beyond these three utilities, you need a designated space. We provide a detailed footprint drawing so your team can pour a simple concrete slab in the right location, ready for when the equipment arrives.

Your Site Preparation Checklist

Being prepared is key. Here is what your facility needs to provide.

- Electrical Power: A dedicated circuit with the correct voltage and amperage to power the main compressor motor and control panel. We will provide the exact specifications early in the planning phase.

- Cooling Water: A reliable loop from a cooling tower or chiller that can supply water at the required temperature and flow rate. This is critical for maintaining system efficiency and protecting the equipment.

- Instrument Air: A clean, dry supply of compressed air to operate the automated control valves. This is typically the same system that powers other pneumatic equipment in your plant.

- Foundation: A flat, level concrete pad built to our specifications. It needs to be strong enough to support the weight of the equipment and located in an area with adequate ventilation.

Can the equipment be integrated with existing production lines?

Your factory is a complex, interconnected system. You need to know that this new equipment will work with your existing setup, not fight against it or create a new bottleneck.

Yes, our systems are designed for seamless integration. We connect to your raw gas source with simple piping and integrate our PLC controller with your plant's main control system (DCS or SCADA) for unified monitoring and operation.

I've worked in enough plants to know that an "island" of technology is a problem. The equipment has to talk to the rest of the factory. Our philosophy at FTL Machine is to make integration as simple as possible. The physical connection is straightforward. We work with your engineers to identify the best tie-in point to tap into the raw CO₂ stream, often a simple pipe flange. The more important integration happens at the control level. Our recovery plant operates on its own PLC, which is the brain that automates its functions. We then connect this PLC to your main plant control system. This allows your central control room operators to see the status of the CO₂ system, monitor its purity and output, and receive any alarms, all on the same screens they already use to run the rest of the plant. This creates a single, unified operational view.

Two Levels of Integration

We ensure our system becomes a natural part of your facility.

- Physical Integration: This involves the "hardware" connections. We design the piping to connect our system's inlet to your CO₂ source and the outlet to your storage tank or point of use. We carefully plan pipe routes and valve locations to fit within your existing infrastructure and ensure easy maintenance access.

- Control System Integration: This is the "software" connection. We use standard industrial communication protocols like Modbus or Ethernet/IP to link our PLC to your main Distributed Control System (DCS) or SCADA system. This allows for a two-way flow of information, enabling centralized control and making the CO₂ plant just another manageable asset on your main dashboard.

Conclusion

A successful CO₂ recovery installation is built on clear planning. By understanding the timeline, utility needs, and integration steps, you can ensure your project is smooth, on-budget, and highly effective.

You may also be interested in:

Why is CO₂ recovery technology gaining popularity worldwide?

Why is CO₂ recovery technology gaining popularity worldwide? You see headlines about carbon capture everywhere. But you wonder if it's

Read more

How is a CO₂ recovery system designed to fit different industries?

How is a CO₂ recovery system designed to fit different industries? You're under pressure to implement a CO₂ recovery solution.

Read more

How energy-efficient are today’s CO₂ recovery technologies?

How energy-efficient are today’s CO₂ recovery technologies? You want to recover CO₂, but you fear that high electricity bills will

Read more