What are the primary disadvantages of Carbon Capture and Storage (CCS)?

•

What are the primary disadvantages of Carbon Capture and Storage (CCS)?

You're considering CCS, but the massive costs and operational risks are a huge concern. The fear of a major energy penalty and long-term storage liabilities is very real.

The primary disadvantages are its high capital and operational costs, the significant "energy penalty" that reduces a plant's net output, and the substantial challenges and risks associated with transporting and permanently storing CO₂ underground, including potential leakage and induced seismic activity.

As an engineer on the front lines of this technology, I see the incredible potential of CCS every day. But I also have honest conversations with clients about the very real challenges. A CCS system isn't just another piece of equipment; it's a massive, integrated project with its own costs, energy demands, and long-term responsibilities. Confronting these disadvantages head-on is the only way to design a project that is both technically sound and economically viable. Let's break down what these challenges really mean for your operation.

What are the economic costs and energy penalties of CO2 recovery?

You're looking at the massive upfront cost of a capture plant. But the real surprise is the ongoing 'energy penalty' that forces you to burn more fuel just to stand still.

The economic costs include high capital expenditure for the capture plant itself. The "energy penalty" is a major operational cost, as the capture process, especially regenerating solvents with steam, consumes a significant portion (15-25%) of the power plant's own energy output, increasing fuel costs.

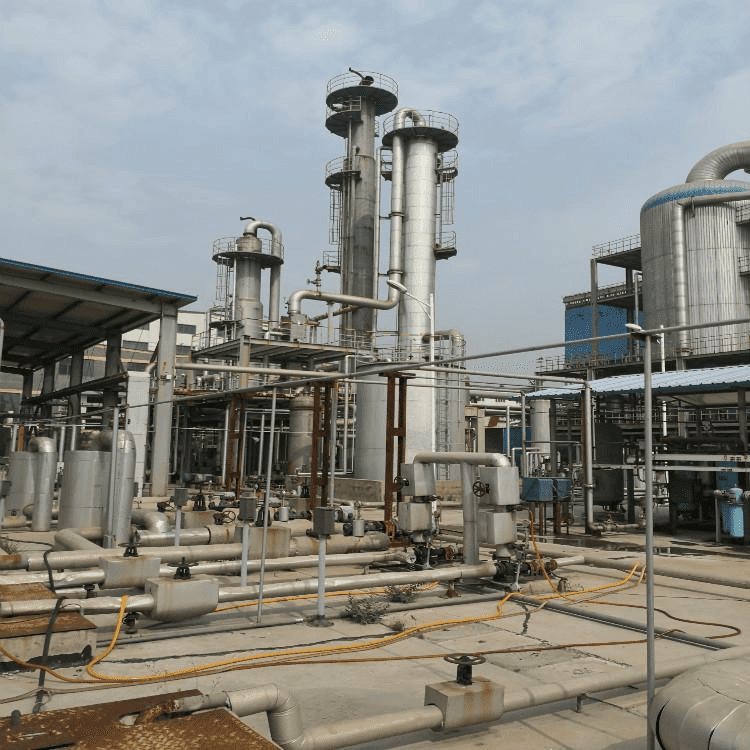

I often describe a carbon capture facility as a chemical plant that you have to build right next to your power plant. It has its own multi-million dollar price tag, and it needs a lot of energy to run. This energy has to come from somewhere, and in most cases, it comes directly from the main plant. This is the "energy penalty." You're essentially diverting a large chunk of the steam or electricity you produce just to power the capture process. This means to sell the same amount of electricity as before, you have to burn more fuel.

Breaking Down the Costs

Both the initial investment (CapEx) and the ongoing running costs (OpEx) are significant hurdles.

Capital vs. Operational Costs

The costs can be broken down into two main categories:

- Capital Expenditure (CapEx): This is the upfront cost to build the capture, compression, and dehydration units. It includes everything from the large absorber and stripper columns to pumps, heat exchangers, and control systems. For a large power station, this can easily run into the hundreds of millions or even billions of dollars.

- Operational Expenditure (OpEx): This is the ongoing cost to run the plant. The biggest component is the energy penalty. Other costs include solvent replacement, maintenance of the new equipment, and labor costs for additional staff.

| Cost Component | Description | Financial Impact |

|---|---|---|

| CapEx | Building the capture plant and related infrastructure. | Massive initial investment and financing costs. |

| Energy Penalty | Energy (steam/electricity) diverted from the main plant to run the process. | Increased fuel consumption; reduced saleable output. |

| Solvent Makeup | Replacing amine solvent that degrades over time. | A continuous consumable material cost. |

| Maintenance | Maintaining the new chemical processing equipment. | Added maintenance budget and potential downtime. |

What are the risks of long-term geological CO2 storage (leakage, seismicity)?

You've captured the CO₂—a huge achievement. But now you have a new problem: you're responsible for keeping it locked away underground, potentially forever, and that comes with some serious long-term risks.

The primary long-term risks are slow, gradual leakage back into the atmosphere, which would negate the climate benefit, and the potential for the injection process to induce minor seismic activity (earth tremors) in geologically sensitive areas.

This is the part of the CCS chain that extends far beyond my equipment. Once my systems capture and compress the CO₂, it gets handed off for transport and storage. The goal is to inject it deep underground into porous rock formations, like old oil and gas reservoirs, and have it stay there for centuries. While geologists are confident in selecting secure sites, there's no such thing as zero risk. We have to plan for the possibility of very slow leaks over a long time, and we have to monitor injection sites carefully to ensure they remain stable.

Secure Containment Challenges

Ensuring the permanence of storage is the ultimate goal, but it requires careful site selection and continuous monitoring.

The Risk of Leakage

The CO₂ is injected into a porous rock layer and is trapped there by a non-porous layer of caprock above it, like a lid on a container. The main risk is that this CO₂ could find a pathway to escape over time.

- Old Wells: Abandoned exploration wells that were not sealed properly can act as conduits.

- Natural Faults: Geologic faults in the rock could provide an escape route if the pressure becomes too high.

- Caprock Integrity: The caprock itself might have weaknesses that are not detected during initial surveys.

The consequence of a leak is that the captured carbon is re-released into the atmosphere, undoing the environmental benefit and financial investment.

Induced Seismicity

The process of injecting large volumes of fluid into the ground changes the pressure within the rock formations. This can, in some cases, lubricate existing faults and cause them to slip, resulting in minor earthquakes. While the vast majority of these are too small for people to feel, the risk must be managed through careful monitoring of seismic activity and by controlling injection pressures and rates to stay well below established safety thresholds.

How does Carbon Capture affect the overall efficiency of a power plant?

Your plant is designed to be as efficient as possible. But adding carbon capture introduces a new process that consumes a large amount of the very energy you are trying to produce and sell.

Carbon capture significantly reduces a power plant's net efficiency. The process requires substantial energy, primarily steam, to regenerate the capture solvents. This parasitic load can decrease the plant's net power output by 15-25%, a serious financial and operational impact.

This is probably the single biggest challenge my clients face. A modern power plant is a finely tuned machine, optimized to convert as much fuel into electricity as possible. When we add a capture unit, we are essentially bolting on a system that is a net energy consumer. For a typical coal-fired power plant, an efficiency of around 40% might drop to about 30% after adding capture. This means for every four truckloads of coal it burned before, it now needs to burn five to produce the same amount of electricity for the grid.

The Source of the Efficiency Loss

The "energy penalty" is not a small rounding error; it's a fundamental consequence of the laws of thermodynamics required for the separation process.

- Solvent Regeneration: The vast majority of the energy is used in the stripper column. Here, a massive amount of low-pressure steam, extracted from the power plant's own turbines, is used to heat the rich amine solvent and break the bond with the CO₂, releasing it for capture.

- Compression: After the CO₂ is separated, it must be compressed into a dense, liquid-like state for transport via pipeline. This compression process is energy-intensive and requires large, powerful machinery.

- Pumps and Auxiliaries: Additional pumps, blowers, and cooling systems for the capture plant also consume electricity, adding to the overall parasitic load.

This efficiency drop means higher fuel costs and a lower return on investment for the plant owner unless there are strong financial incentives, like carbon taxes or credits, to offset this loss.

Conclusion

The primary disadvantages of CCS are its high capital costs and the significant energy penalty that reduces plant efficiency. Furthermore, the long-term risks associated with geological storage, such as potential leakage and induced seismicity, present substantial long-term challenges.

You may also be interested in:

Why is CO₂ recovery technology gaining popularity worldwide?

Why is CO₂ recovery technology gaining popularity worldwide? You see headlines about carbon capture everywhere. But you wonder if it's

Read more

How is a CO₂ recovery system designed to fit different industries?

How is a CO₂ recovery system designed to fit different industries? You're under pressure to implement a CO₂ recovery solution.

Read more

How energy-efficient are today’s CO₂ recovery technologies?

How energy-efficient are today’s CO₂ recovery technologies? You want to recover CO₂, but you fear that high electricity bills will

Read more