What are the current carbon capture technologies?

•

What are the current carbon capture technologies?

Feeling overwhelmed by all the carbon capture options available today? You need to know which technologies are practical and proven, making it hard to choose the right one for your facility.

Current leading technologies include post-combustion capture with amine scrubbing, pre-combustion capture, and oxy-combustion. For industrial CO2 recovery, methods like membrane separation, cryogenic distillation, and pressure swing adsorption (PSA) are also widely used, especially for high-purity sources.

As an engineer in this field, I've seen how confusing the landscape can be. Each technology has its place, but not every solution is right for every problem. The key is to understand the fundamentals of each method so you can see which one aligns with your specific operational goals. Let's dig into the details.

What is the technology for carbon dioxide recovery?

Are you trying to turn a waste gas stream into a usable product? The specific recovery technology you choose will determine the efficiency and purity of your final CO2 product.

CO2 recovery technology focuses on separating and purifying CO2 from industrial gas streams. The main methods are chemical absorption using solvents, physical separation with membranes or pressure swings (PSA/VSA), and cryogenic distillation which liquefies the CO2 for easy separation.

Recovery is different from just capturing CO2 from a power plant flue. It’s about creating a high-quality product. I’ve worked on many projects, from breweries to chemical plants, where the goal wasn't just capture, but purification for reuse. The technology choice is critical here.

Matching Technology to the Source

The best technology depends entirely on your CO2 source. For a high-concentration stream, like from brewery fermentation, the job is simpler. You need to focus on purification. For lower-concentration streams, the separation part is the main challenge. I find a simple breakdown helps clarify this for my clients. It's about looking at your gas stream's properties and matching them with the strengths of each technology. A good match means higher efficiency and lower operational costs.

| Technology | Best For | Key Advantage |

|---|---|---|

| Amine Scrubbing | Low-concentration flue gas (Power plants) | Mature, high capture rate |

| Membrane Separation | Medium-concentration streams (Natural gas) | Modular, simple operation, no chemicals |

| Cryogenic Distillation | High-concentration streams (>90% CO2) | Produces high-purity liquid CO2 directly |

| PSA / VSA | High-concentration streams | Low energy, effective for purification |

Which is the most widely used CO2 separation technology?

With so many options, do you just want to know what works? Sticking with a proven, reliable technology can reduce risk and ensure your project's success from the start.

Amine scrubbing, a form of chemical absorption, is the most widely used and mature technology for large-scale CO2 capture, especially from flue gases in power plants and industrial facilities. It is trusted for its high efficiency and reliability.

Amine scrubbing is the industry workhorse for a reason. It's been around for decades and is incredibly effective at pulling CO2 out of mixed gas streams. I've designed and commissioned several of these systems. They are robust and get the job done. However, "most widely used" doesn't always mean "best for everyone."

Why Amine Scrubbing Dominates (and When It Doesn't)

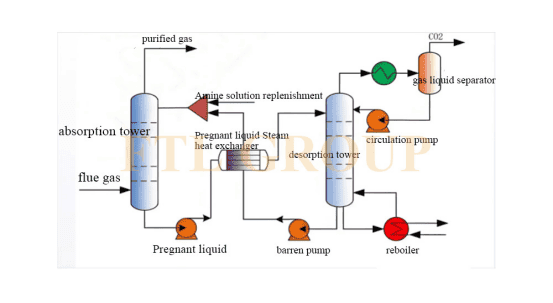

This method works by passing a gas stream through a liquid amine solution. The amine selectively absorbs the CO2. Then, the solution is heated to release the pure CO2, and the amine can be reused. Its strength lies in handling large volumes of low-concentration gas, which is why power plants love it. But there are trade-offs. The heating step, called regeneration, uses a lot of energy. The amines can also be corrosive. For processes that already have a high concentration of CO2, like brewing or certain chemical reactions, other technologies like cryogenic or membrane systems are often much more energy-efficient and cost-effective. They are designed for purification rather than bulk separation from a dilute source.

What are the drawbacks of carbon capture?

You've heard the promises, but what about the problems? Understanding the potential downsides is crucial for making a smart investment and avoiding any unexpected operational headaches.

The main drawbacks are the high initial capital cost and the significant energy consumption, known as the "energy penalty," required to operate the system. Other concerns include potential solvent degradation and the logistical challenge of transporting and storing the captured CO2.

I believe in being transparent about these challenges. No technology is a magic bullet. Yes, these systems cost money to build and run. The energy penalty is real because separating gases is an energy-intensive process. But these drawbacks can be managed with smart engineering.

Mitigating the Challenges

The key is to target the right applications. The drawbacks are most severe when trying to capture CO2 from very dilute sources. At FTL Machine, our entire focus is on sources where the CO2 is already highly concentrated. For a brewery or an ethanol plant, the gas stream is already over 99% pure CO2. In these cases, the "capture" step is minimal. The system's job is purification. This dramatically reduces the energy penalty. The cost issue is addressed by reusing the CO2 on-site. When you stop buying CO2 from an external supplier, the system starts paying for itself. This turns the conversation from cost and drawbacks to savings and return on investment.

Conclusion

Current technologies offer effective ways to capture and recover CO2. By matching the right method to your specific needs, you can overcome the drawbacks and create a valuable, sustainable solution.

You may also be interested in:

Why is CO₂ recovery technology gaining popularity worldwide?

Why is CO₂ recovery technology gaining popularity worldwide? You see headlines about carbon capture everywhere. But you wonder if it's

Read more

How is a CO₂ recovery system designed to fit different industries?

How is a CO₂ recovery system designed to fit different industries? You're under pressure to implement a CO₂ recovery solution.

Read more

How energy-efficient are today’s CO₂ recovery technologies?

How energy-efficient are today’s CO₂ recovery technologies? You want to recover CO₂, but you fear that high electricity bills will

Read more