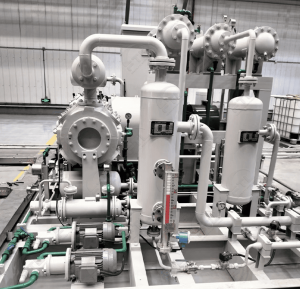

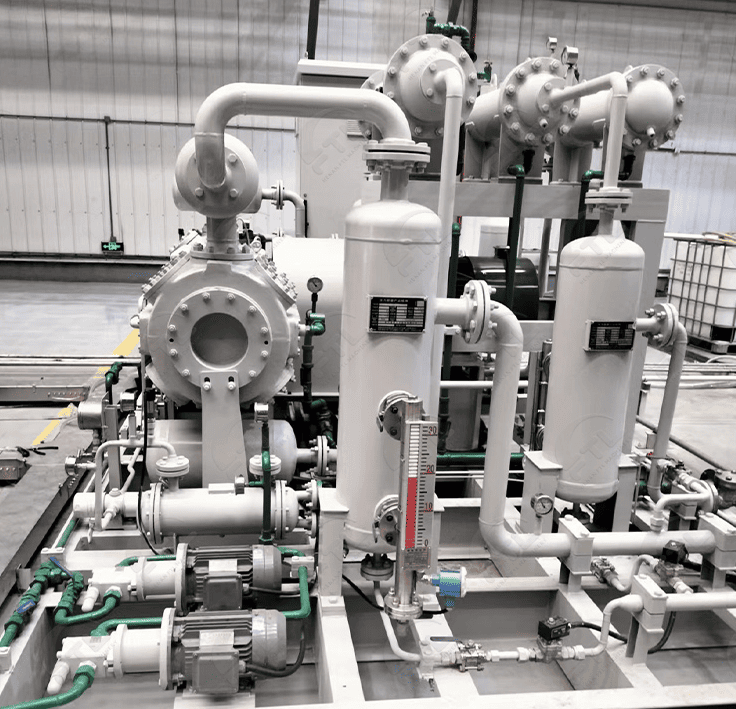

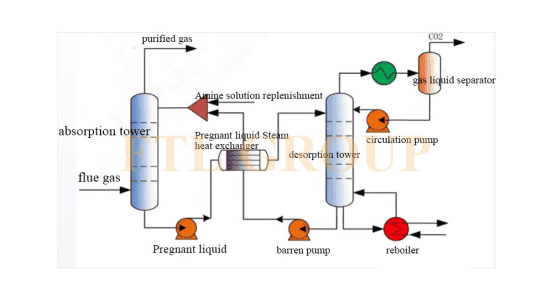

It is suitable for flue gas emission scenarios such as coal-fired power plants, boiler plants, and cement plants. The system uses MEA solution to absorb CO₂ (with a concentration of 8%–35%) at room temperature, then releases CO₂ through heating and desorption, and obtains high-purity products after purification and drying.

CO2 product details

MEA CO2 Capture

MEA CO2 capture technology

Product Overview

- Customized design for different flue gas components to reduce investment and energy consumption.

- Small footprint and easy installation.

- Equipped with a DCS (Distributed Control System) for easy operation and 24-hour continuous operation.

- All components in contact with CO₂ are made of stainless steel, ensuring safety and stability.

Capture in industrial flue gas CO2

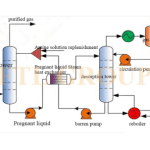

Absorption (absorption tower)

The high-temperature flue gas is first cooled and then enters from the bottom of the absorption tower.

The dilute MEA solution of the absorbent is sprayed down from the top of the absorption tower.

Inside the absorption tower, CO2 in the flue gas undergoes a reversible chemical reaction with the MEA solution, generating stable compounds (mainly monoethanolamine bicarbonate).

Other gas components (such as nitrogen and oxygen) do not react and escape from the top of the tower.

The MEA solution that has absorbed CO2, also known as the rich solution, is collected from the bottom of the absorption tower and pumped to the desorption tower.

Desorption/regeneration (desorption tower)

After the rich liquid enters the desorption tower, it is heated by the heat provided by the reboiler at the bottom of the tower.

Under high-temperature conditions, the previously occurring chemical reactions are reversed, and CO2 is released from the MEA solution, becoming a high-purity gas.

The regenerated MEA solution, also known as the lean solution, flows out from the bottom of the tower, is cooled and then pumped back into the absorption tower to form a closed-loop circulation.

The high-purity CO2 released is compressed and liquefied for storage or reuse.

Related Products