The LCO₂ (Liquid Carbon Dioxide) Tank Container is a specialized container designed for long-distance storage and transportation of liquid CO₂. It is widely used in CCS (Carbon Capture and Storage), food freezing, chemical engineering, and medical industries. Adopting high-vacuum multi-layer insulation technology, it can effectively reduce heat transfer and maintain the low-temperature state of the liquid carbon dioxide inside. Typically made of high-strength materials, the tank container features pressure resistance, corrosion resistance, and excellent thermal insulation performance, ensuring the safety and stability of liquid CO₂ during long-distance transportation.

CO2 product details

LCO2 Liquid Carbon Dioxide Tank Container

Special transportation equipment for liquid LCO2

Product Overview

- International certifications for transportation compliance: The container has passed strict certifications from multiple internationally renowned classification societies, including CCS (China Classification Society), BV (Bureau Veritas), and LR (Lloyd's Register). This not only confirms its outstanding safety performance and structural reliability but also ensures that it fully complies with international transportation regulations for sea, land, and rail transportation worldwide.

- Customizable design for diverse needs: The LCO₂ tank container can be custom-designed to meet different application scenarios and customer requirements. For example, its volume, working pressure, and external structure can be adjusted to adapt to specific loading requirements and operating environments.

- Lightweight design, improving loading efficiency: By using high-strength, lightweight materials, the tank achieves a lighter weight while maintaining safety. This directly increases the container's payload capacity (loading rate), reduces transportation costs per shipment, and improves overall economic efficiency.

- Low evaporation rate, ensuring superior insulation performance: Thanks to advanced insulation technology, this container has an extremely low evaporation rate. This means that CO₂ loss during long-term transportation or storage is minimal, ensuring the quantity and quality of the final product delivered.

- Real-time monitoring , enhancing transport safety: Some models offer optional sensors to monitor key parameters such as temperature, pressure, and liquid level inside the tank in real time. This data can be transmitted remotely, allowing operators to monitor the tank's operating status, detect potential risks promptly, and take corrective actions to ensure absolute safety during transportation.

Thermal insulation and pressure control

Thermal Insulation Structure:

The tank features a double-walled design comprising a stainless steel inner liner and a carbon steel outer shell. The space between these layers is filled with high-efficiency insulation material and evacuated to a high vacuum. This configuration minimizes external heat transfer, enabling LCO₂ to maintain its **cryogenic liquid state (approximately -20°C) under high pressure (approximately 2.0-2.2 MPa)** during transport.

Gas-Liquid Equilibrium:

Within the tank, liquid CO₂ maintains a dynamic equilibrium with the overlying gaseous CO₂. When tank temperature rises, partial liquid vaporizes, causing pressure to increase; conversely, pressure decreases.

Pressurization and Discharge:

For discharge convenience, tanks are typically equipped with a pressurizer. The pressurizer utilizes the temperature difference between the liquid and gas inside the tank to heat and vaporize part of the LCO₂, increasing the internal pressure. This allows the liquid CO₂ to be smoothly expelled through the bottom valve.

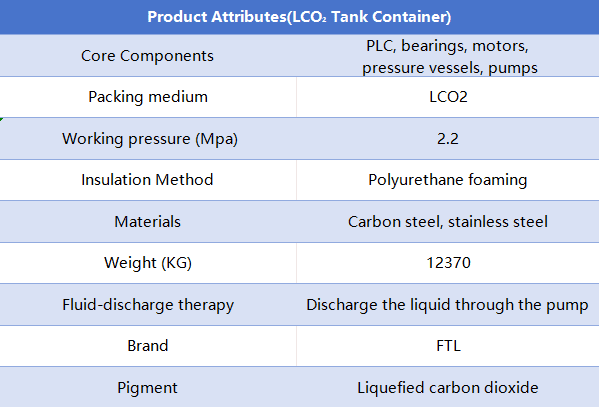

Product Specifications

Related Products