Industrial-grade CO₂ recovery equipment is specifically designed to meet the demand for large quantities of high-purity carbon dioxide in industries such as chemical engineering, welding, and refrigeration. Unlike food-grade equipment that requires extremely strict purity standards, industrial-grade equipment focuses more on the economy of investment and operation as well as the long-term stability of the system. The purity of the CO₂ it produces typically reaches over 99%.

CO2 product details

Industrial grade CO2 equipment

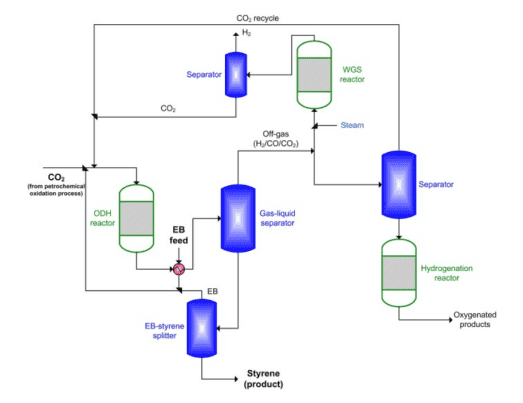

A system for industrial use of carbon dioxide

Product Overview

- Low investment and operating costs: The equipment is optimized in design to maximize energy efficiency and minimize maintenance requirements. Compared to producing CO₂ from scratch, recovering it from industrial waste gas can significantly reduce raw material costs and energy consumption, thereby achieving lower overall operating costs.

- Automated control with remote monitoring: The system usually adopts PLC (Programmable Logic Controller) or DCS (Distributed Control System) for automated control. This not only improves the precision and stability of operation but also supports remote monitoring and fault diagnosis, greatly reducing manual intervention and ensuring continuous and safe production.

- Robust and durable, suitable for harsh environments: The equipment is manufactured using high-strength, corrosion-resistant materials, capable of withstanding harsh industrial environments such as high temperatures, high humidity, or corrosive gases, ensuring long-term stable operation and service life of the equipment.

- Customized design for different gas sources: The equipment can be custom-designed according to the composition of different industrial gas sources (such as flue gas from coal-fired power plants, waste gas from cement kilns, etc.). This flexibility ensures that the equipment can efficiently handle various gas sources and maximize recovery efficiency.

simplifies certain fine purification stages

Purification:

The raw CO₂ gas extracted from industrial waste gas first enters the purification unit. Here, impurities such as sulfides, nitrogen oxides, and water vapor are removed through adsorption, scrubbing, or catalytic conversion.

Compression:

The purified gas is pressurized by a high-pressure compressor, preparing for subsequent liquefaction and separation.

Scrubbing: Water or alkaline solution scrubbers remove water-soluble impurities such as sulfides and ammonia.

Drying: Utilizes desiccants (such as molecular sieves or silica gel) to remove moisture from the gas, preventing ice formation and equipment blockage during subsequent cryogenic liquefaction.

Adsorption: Activated carbon adsorption beds remove some organic impurities and odors.

Cooling and Separation:

The high-pressure gas undergoes deep cooling through a refrigeration system. Under low temperature and high pressure, CO₂ is converted into a liquid state, while non-condensable gases such as nitrogen and oxygen remain in a gaseous state. Through physical separation technologies such as distillation columns, liquid CO₂ is effectively separated from residual gaseous impurities.

Refining and Storage:

The separated liquid CO₂ undergoes further refining to ultimately obtain an industrial-grade product with a purity of 99% or higher. This product is then sent to storage tanks or directly used in industrial applications.

Related Products