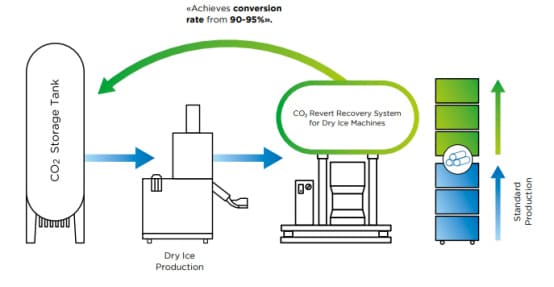

The low-temperature tail gas generated during dry ice production can be recycled. Approximately 1.2 tons of liquid CO₂ can be recovered for every ton of dry ice produced, significantly reducing production costs. By applying technologies such as recovery, liquefaction, and separation to the low-temperature CO₂ gas generated in the dry ice production process, food-grade liquid CO₂ products can be obtained, reducing the amount of liquid CO₂ consumed per unit of dry ice production.

CO2 product details

Dry ice tail gas recovery system

The tail gas of CO2 is recovered

Product Overview

- Mature process with stable operation.

- Low energy consumption and fast liquefaction speed.

- High degree of automation with remote monitoring capability.

- Customizable process according to user requirements.

The utilization rate of CO2 has been improved.

Tail Gas Capture:

Hoods or ducts are installed near the dry ice press or pelletizer to collect the low-pressure CO2 tail gas generated during dry ice production.

Gas Purification:

Collected exhaust gas may contain trace impurities such as oil residue, moisture, and dust. These gases first enter a purification unit where filters and adsorbents (e.g., activated carbon) remove impurities to protect downstream compressors and equipment.

Pressurized Compression:

Purified CO₂ gas enters multi-stage compressors. Due to the low pressure of the exhaust gas, compressors elevate its pressure to the high pressure required for liquefaction (typically 60-80 bar).

Condensation and Liquefaction:

The compressed, high-temperature, high-pressure CO₂ gas enters a condenser. Cooling media (such as cooling water or refrigerant) lower its temperature, causing it to condense into high-pressure liquid CO₂.

Return to Storage Tank:

The liquefied CO₂ is directly transported back to the liquid CO₂ storage tank, where it mixes with fresh liquid CO₂ and re-enters the dry ice production process.

Related Products