A CO2 gasification station typically consists of three main modules: a storage module, a vaporization module, and a pressure regulation module. These three modules work together to convert stored carbon dioxide into gaseous form, ensuring a reliable and efficient supply of CO2 for various industrial applications, such as food processing, beverage carbonation, refrigeration, or as a raw material for chemical synthesis.

CO2 product details

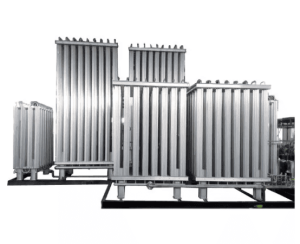

CO2 Vaporization Station

CO2 gas supply system

Product Overview

- Modular design for easy installation and expansion.

- Stable output, suitable for applications across multiple industries.

- Automatic monitoring, safe and reliable.

Vaporizer

Storage module:

This module is responsible for storing CO2 in an appropriate form. Depending on the specific application and scale of the facility, CO2 can be stored in various forms, such as liquid CO2 tanks or compressed gas cylinders. The storage module ensures a stable and reliable supply of carbon dioxide for the gasification process.

Vaporization Module:

The vaporization module is where the stored CO2 is converted from its liquid or solid state to gaseous CO2. This is typically achieved by applying heat using an ambient temperature evaporator or other heating methods. Vaporization is a crucial step in the gasification process, as it prepares the carbon dioxide for further processing and utilization.

Pressure regulation module:

Once CO2 is vaporized, its pressure needs to be regulated to the level required for the specific application or downstream process. The pressure regulation module ensures that the gaseous CO2 maintains the pressure necessary for safe handling, storage, and utilization. This module may include a pressure regulator, control valves, and a monitoring system to maintain optimal operating conditions.

Related Products