The carbon dioxide storage tank is a double-layer vacuum-insulated cryogenic tank designed for the storage and transportation of liquid CO₂. It is widely used in the food freezing, chemical engineering, welding, and medical industries. Featuring a double-layer structure, the space between the inner and outer containers is filled with insulating material and evacuated to a vacuum to reduce heat transfer, thereby maintaining the low-temperature state of the liquid carbon dioxide inside. Typically made of high-strength materials, the tank exhibits pressure resistance, corrosion resistance, and excellent thermal insulation performance.

CO2 product details

CO2 Storage Tank

Pressure vessels for storing LCO2

Product Overview

- Advanced insulation technology for extended vacuum service life.

- High-quality appearance, ensuring aesthetics and durability.

- Integrated pipeline system for easy operation. High-quality appearance, ensuring aesthetics and durability.

- Customizable material options for the inner container.

High-pressure low-temperature liquefaction.

Liquefied Storage:

After being compressed and cooled at the plant, CO₂ gas transforms into liquid CO₂, which is then pumped into storage tanks. The tanks maintain a specific high pressure (approximately 1.8–2.2 MPa) and low temperature (around -20°C) to ensure the CO₂ remains in liquid form.

Thermal insulation protection:

The inner tank and outer shell of the storage tank are usually filled with highly efficient thermal insulation materials (such as vacuum powder or polyurethane foam), forming a vacuum interlayer. This insulating layer can effectively isolate external heat, minimize heat transfer to the greatest extent, and thereby slow down the evaporation of liquid CO2.

Pressure Control:

Despite insulation, external heat gradually penetrates, raising internal temperatures and causing partial vaporization of liquid CO₂, leading to incremental pressure buildup. To prevent excessive pressure, tanks are equipped with safety valves that automatically vent excess gas when pressure exceeds preset limits, ensuring operational safety.

Pressurization and Gas Supply:

When liquid CO₂ needs to be transported or vaporized for use, the pressurizer on the tank activates. Utilizing the temperature difference between the liquid and gas phases inside the tank, the pressurizer heats and vaporizes a portion of the liquid CO₂, increasing the internal pressure. This forces the liquid CO₂ out from the tank bottom, delivering it to external usage equipment or vaporizers.

No process flow diagram available.

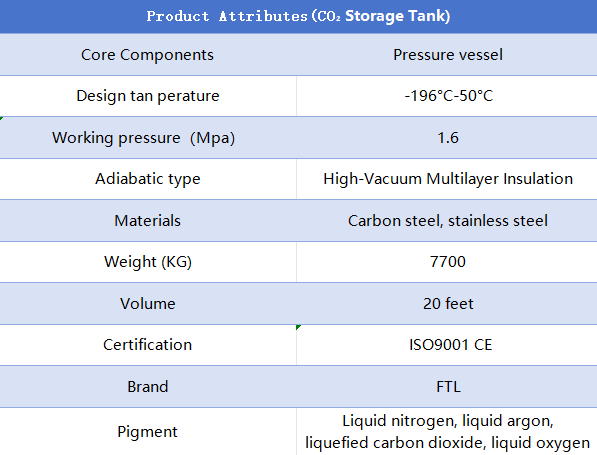

Product Specifications

Related Products