This technology utilizes the principle of selective permeability to achieve natural gas decarbonization. The membrane system features a compact design, small footprint, and low operating costs. The CO2 separation membrane is an efficient membrane material used for natural gas decarbonization. By leveraging the membrane’s preferential permeability to CO2, it can separate CO2 from natural gas under a certain pressure difference. This technology allows CO2 in the natural gas to preferentially permeate through the selective membrane, resulting in a product gas with lower CO2 content on the non-permeable side, thus purifying the natural gas.

CO2 product details

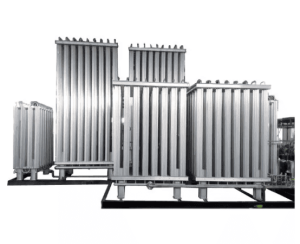

CO2 Separation Membrane

The separated semi-permeable membrane

Category:

CO2 Related Products

Product Overview

- Simple design and easy integration with other processes: The membrane separation system is compact, lightweight, and requires minimal space. It can function as a standalone decarbonization unit or be easily integrated into existing natural gas processing systems, seamlessly combining with processes such as liquefaction and compression.

- Economically efficient and suitable for large-scale applications: Compared to traditional carbon capture technologies such as amine absorption, membrane separation systems require fewer chemicals and consume less energy. Their lower operating and maintenance costs also make them an economical choice for large-scale natural gas decarbonization.

- Easy operation and safe and reliable performance: The entire system is highly automated, making operation simple. Because it does not involve complex chemical reactions or high-temperature, high-pressure environments, the system's safety and reliability are significantly enhanced.

- No secondary pollution, energy-efficient and environmentally friendly: Membrane separation is a physical process that does not produce any secondary pollutants, thus meeting environmental protection standards. Furthermore, the low energy consumption of the process contributes to the sustainable and environmentally friendly production of natural gas.

Dissolution-diffusion model

The key to CO₂ separation membranes lies in their unique polymer material. The microstructure of this material determines its permeability rate for different gas molecules. When a natural gas mixture containing CO₂ enters the membrane module:

Permeation:

Because CO₂ molecules are smaller and more soluble than methane molecules, they can dissolve into the membrane and diffuse to the other side (permeation side) more quickly.

Retention:

Due to their larger molecular size and slower permeation rate, most methane molecules are retained on the opposite side of the membrane (the non-permeable side).

Separation:

By controlling the pressure difference across the membrane, this separation process can be effectively driven. Ultimately, a product gas with extremely low CO₂ concentration (i.e., purified natural gas) is obtained on one side of the membrane, while a permeate gas rich in CO₂ is obtained on the other side.

Diagram showing the complete CO2 recovery process from capture to purification and storage.

Related Products

Product Categories

CO₂ Capture Plant

CO₂ Recovery Plant

CO₂ Storage & Transport

CO₂ EPC Engineering

CO₂ Related Products