A CO₂ cylinder is a high-pressure container used for storing and transporting carbon dioxide gas. It is typically made of high-strength steel, which can withstand high pressure to ensure the safe storage and use of the gas. CO₂ cylinders are widely applied in fields such as the food and beverage industry, welding, fire protection, medical care, and chemical engineering. There are different capacities and specifications (e.g., 4L, 10L, 40L) based on usage and requirements.

CO2 product details

CO2 Seamless Steel Cylinder

CO₂ storage container.

Category:

CO2 storage and transport

Product Overview

- Diverse classifications for multiple uses: Seamless cylinders can be classified into various types according to different applications—for example, cylinders for fire extinguishing, special cylinders for the food and beverage industry (such as cylinders for soda fountains), industrial cylinders for welding, and small cylinders for laboratory research. This diversity ensures that the most suitable solution can be found for each application.

- High-pressure bearing capacity: Seamless cylinders can withstand a working pressure of up to 15 MPa or higher. This strong pressure resistance is the core guarantee of their safety; even when the gas is compressed to a high density, the integrity of the container can be maintained.

- High-strength alloy steel material: Cylinders are integrally formed from special high-strength alloy steel without any welded joints. This seamless structure eliminates potential safety hazards caused by welding defects, while providing excellent corrosion resistance and durability, significantly extending the service life.

- Multiple capacity and specification options: Seamless cylinders are available in a range of capacities and specifications, from small portable ones to large fixed ones, to meet the precise needs of different application scenarios. Users can flexibly select the most suitable cylinder based on the required CO₂ storage volume and working environment.

CO2 seamless cylinders relies on phase transitions.

With its robust seamless structure and high-pressure resistance, it safely stores carbon dioxide gas inside the cylinder under high-pressure conditions. When the gas needs to be used, a high-pressure valve installed at the cylinder mouth can control the release of the gas, enabling the safe transfer or application of CO₂. The design and manufacture of the cylinder must strictly comply with relevant international and national safety standards (such as ISO, DOT, or GB standards) to ensure absolute safety during filling, transportation, and use.

Filling:

During filling, liquid CO2 is pumped into the cylinder. Due to partial vaporization of the CO₂, the cylinder maintains a liquid-gas equilibrium state internally.

Storage:

When the cylinder is at ambient temperature, the internal pressure remains around 5.7 MPa. As the ambient temperature rises, the liquid CO₂ further vaporizes, causing the internal pressure to increase. Therefore, the cylinder design must withstand a maximum working pressure significantly higher than ambient temperature, typically reaching 15-25 MPa.

No process flow diagram available.

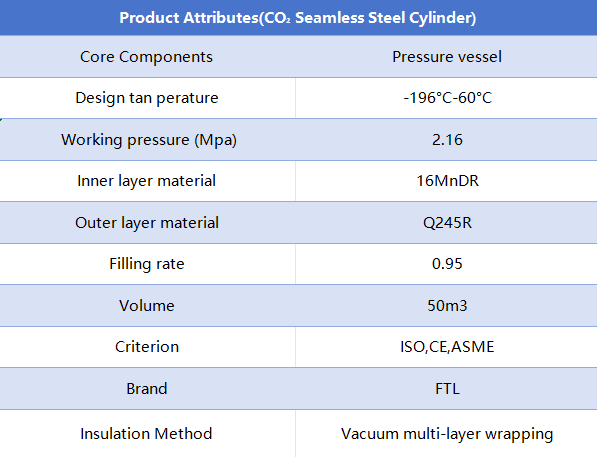

Product Specifications

Related Products

Product Categories

CO₂ Capture Plant

CO₂ Recovery Plant

CO₂ Storage & Transport

CO₂ EPC Engineering

CO₂ Related Products