Industrial gas streams such as natural gas, landfill gas, biogas, blast furnace gas, and associated petroleum gas typically contain a certain proportion of carbon dioxide (CO₂). Its presence not only reduces the combustion calorific value and utilization efficiency of the gas source but also causes severe corrosion to transmission pipelines and equipment. Meanwhile, as a typical greenhouse gas, direct emission of CO₂ will exacerbate global warming and impose environmental pressure. On the other hand, CO₂ is also an important industrial raw material, widely used in welding protection, food and beverage production, and many other industries. Therefore, separating and recovering CO₂ from combustible gases such as methane and carbon monoxide can not only enhance the utilization value of the gas source but also realize resource recycling, which is of great significance.

CO2 product details

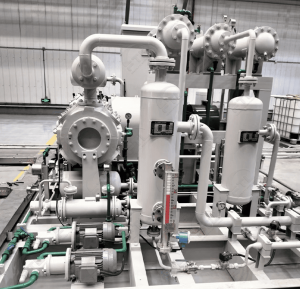

CO2 Membrane Separation Equipment

CO₂ separation

Category:

CO2 capture plant

Product Overview

- CO₂ recovery rate ≥ 95%, purity ≥ 99.5%.

- Methane recovery rate ≥ 99%, purity ≥ 92%.

- Flexible configuration of single-stage or multi-stage membrane separation, suitable for different gas sources.

- Environmentally friendly operation, no secondary pollution, and low energy consumption.

selectively permeable membran

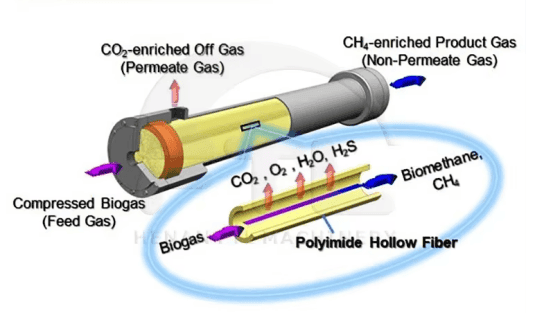

After the mixed gas undergoes dust removal, desulfurization, pressurization, drying, and purification, it enters the membrane separation unit. The membrane has preferential permeability to CO₂, forming a retentate stream rich in methane and a permeate stream rich in CO₂. The methane retentate stream is output as fuel gas, while the CO₂ permeate stream is compressed and condensed to obtain high-purity liquid CO₂.

Diagram showing the complete CO2 recovery process from capture to purification and storage.

Related Products

Product Categories

CO₂ Capture Plant

CO₂ Recovery Plant

CO₂ Storage & Transport

CO₂ EPC Engineering

CO₂ Related Products