A carbon dioxide injection pump is a device used to inject liquid CO₂ into underground reservoirs or other target areas. This equipment uses a high-pressure pump to pressurize the liquid CO₂ and inject it underground. It is widely used in enhanced oil recovery, carbon capture and storage (CCS), and supercritical CO₂ extraction. Carbon dioxide injection pumps have advantages such as compact design, high efficiency, low noise, and easy operation and maintenance. They can operate stably under high pressure, ensuring the safety and efficiency of the injection process. Used for high-pressure injection of liquid CO₂, it finds wide application in enhanced oil recovery, CCS, and supercritical extraction.

CO2 product details

CO2 Filling Pump

CO2 Pressurization Pump

Category:

CO2 Related Products

Product Overview

- Horizontal design saves space: The horizontal structure allows for a smaller footprint, making it easier to install and arrange in limited spaces, thus improving space utilization.

- High-pressure capability up to 50 MPa: The pump boasts a powerful pressurization capability, reaching up to 50 MPa, easily meeting the needs for filling various high-pressure storage tanks and systems, ensuring efficient and sufficient injection of carbon dioxide.

- Multiple plunger configurations available to meet diverse flow rate requirements: We offer various plunger configurations, allowing flexible selection based on different flow rate needs. Whether for small-scale gas cylinder filling stations or large-scale industrial refilling centers, the right model can be found, ensuring the equipment's versatility and adaptability to specific customer requirements.

- Low noise, high efficiency, reliable operation: Advanced design and precise manufacturing processes ensure low noise and minimal vibration during operation. Furthermore, high efficiency reduces energy consumption, while a robust structure and an optimized sealing system guarantee long-term stable and reliable operation, significantly lowering maintenance costs.

Hydraulically driven or electrically driven

The core function of this pump is to use mechanical energy to increase the pressure of liquid CO₂ so that it can be transported safely and efficiently to high-pressure storage tanks or pipelines. The entire process is carried out under strict temperature and pressure control, ensuring that the CO₂ remains in a liquid state throughout the filling process, thus maximizing filling efficiency and guaranteeing operational safety.The specific working process is as follows:

Suction:

The pump draws in liquid CO₂ from a low-temperature storage tank (such as an ISO tank or storage vessel) at low temperature and low pressure.

The entire process is carried out under strict temperature and pressure control, ensuring that the CO₂ remains in a liquid state throughout the filling process, thus maximizing filling efficiency and guaranteeing operational safety.

Pressurization:

Liquid CO₂ is compressed to a predetermined high pressure by the reciprocating motion of a piston or plunger.

Discharge:

The pressurized liquid CO₂ is safely injected into the target area, such as high-pressure cylinders, vehicle storage tanks, or industrial application systems

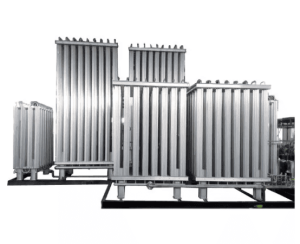

Diagram showing the complete CO2 recovery process from capture to purification and storage.

Related Products

Product Categories

CO₂ Capture Plant

CO₂ Recovery Plant

CO₂ Storage & Transport

CO₂ EPC Engineering

CO₂ Related Products