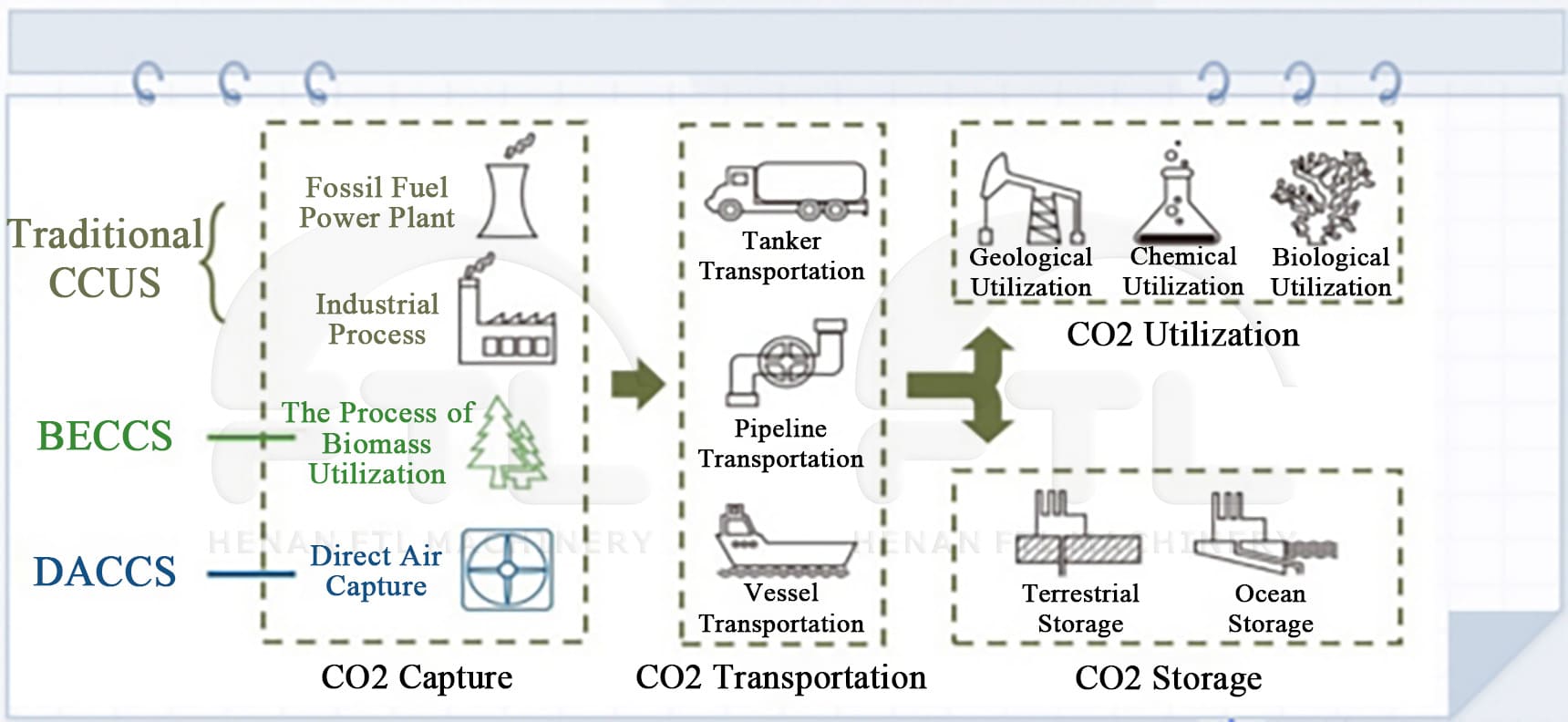

Carbon capture and utilization (CCUS) system for coal-fired power plants

Core Performance Metrics

Annual CO₂ Recovery

50,000 tons of CO₂

Reducing carbon footprint while creating value

collection efficiency

92%

Exceeding food-grade quality standards

System availability

98.5%

Compared to conventional systems

Carbon emission reduction cost

$35 per ton

Fast return on investment

Client Name

Indonesia's state-owned electricity company (PLN)

Project Location

Semarang City, Java Island

Commissioning Date

November 2021

Equipment Model

FTR-5000-CCUS

Project Background & Challenges

Client Pain Points

-

ndonesia's new carbon emission regulations require

-

"Complex flue Gas composition (SOx/NOx interference)

-

"Challenge of High Humidity in Island Environment" │"A CO₂ reuse solution is required

On-site Conditions

The existing fermentation facility with outdated CO₂ emission systems requiring urgent environmental and efficiency upgrades.

Our Solution

Customized CCUS solutions

Our comprehensive solution captures, purifies, and recycles CO₂ from the fermentation process, creating a closed-loop system that minimizes emissions while producing food-grade CO₂.

Installation Phase

Professional installation of the CO₂ recovery system with minimal disruption to existing operations.

Completed Setup

The fully integrated system after installation, ready for operational testing and optimization.

Project Results

Performance Improvements

性能改进

```html

| Metric | Before | After | Improvement |

|---|---|---|---|

| CO₂ Capture Efficiency | 85% | 95% | +10% |

| Energy Penalty | 30% | 22% | -8% |

| Cost per Ton CO₂ | $65 | $48 | -26% |

"Our power plant's carbon capture system has achieved dual benefits - reducing emissions by 120,000 tons annually while generating $2.8M in carbon credit revenue. The modular design allowed seamless integration with our existing infrastructure, proving environmental responsibility can coexist with economic returns."

Nguyen Van Minh

Operations Director, Vietnam Beverages Ltd.

Equipment Technical Parameters

| Parameter | Specification | Notes |

|---|---|---|

| Flue Gas Capacity | 50,000 Nm³/h | For 300MW power plant |

| Working Pressure | 3.5 MPa | Optimized for high-volume capture |

| Power Consumption | 10MW | Integrated with plant grid |

| Footprint | 30m × 20m | Modular design for expansion |

| CO₂ Capture Rate | 95% | Exceeds industry standards |

| Control System | DCS with SCADA | Plant-wide integration |