Is CO₂ recovery a cost-effective solution for manufacturers?

•

Is CO₂ recovery a cost-effective solution for manufacturers?

You look at your monthly expenses and see a line item for purchased CO₂ that keeps climbing. It's a necessary operational cost, but you feel like you are just burning money on a gas you already produce.

Yes, CO₂ recovery is highly cost-effective for many manufacturers. By producing your own CO₂ for a fraction of the purchase price, most plants see a full return on their investment within 2 to 5 years, turning a major cost center into a source of savings or revenue.

As an engineer myself, I know that a new piece of equipment has to do more than just work—it has to make financial sense. I've spent years helping companies run the numbers on CO₂ recovery, and the results are almost always compelling. We move beyond the technical specifications and get right to the core of the issue: how does this investment impact the bottom line? Let's break down the real costs, the tangible savings, and the long-term financial benefits you can expect from bringing your CO₂ supply in-house.

What is the typical investment and payback period for a CO₂ recovery unit?

You see the potential savings, but a big capital expense is a major hurdle. You need to build a solid business case to get project approval, and that starts with understanding the real investment and payback time.

A CO₂ recovery system's investment can range from a few hundred thousand to several million dollars, depending on capacity. The payback period is typically 2 to 5 years, driven by your scale, local energy costs, and the price you pay for delivered CO₂.

Whenever I start a new project, the first question is always about cost. I explain that the total investment, or CAPEX, includes the equipment itself, plus installation, and integration with the existing facility. The biggest factor is scale. A small brewery needing 1 ton per day has a very different system from a large ethanol plant capturing 300 tons per day. The payback calculation is a straightforward comparison. We look at the annual savings from not buying CO₂ and subtract the new operational costs, or OPEX—mainly electricity for the compressor and periodic maintenance. The result is your net annual saving. Dividing the total investment by this saving gives you the simple payback period. For most of my clients, seeing that number come in under four or five years is what gets the project green-lit.

Breaking Down the Investment

The financial case is built on a clear understanding of costs and returns.

| Plant Size (CO₂ per day) | Estimated CAPEX | Key OPEX Components | Typical Payback Period |

|---|---|---|---|

| Small (1-5 tons) | $300k - $800k | Electricity, Maintenance | 3 - 5 Years |

| Medium (10-50 tons) | $1M - $3.5M | Electricity, Labor, Spares | 2 - 4 Years |

| Large (100+ tons) | $5M+ | Electricity, Full-Time Labor | 1.5 - 3 Years |

The Capital Expenditure (CAPEX) is the upfront cost of the FTL Machine unit, shipping, installation, and commissioning. The Operational Expenditure (OPEX) is the ongoing cost to run the plant. Electricity to power the compressor is the single largest component. Other costs include maintenance consumables like lubricants and filters, and a small amount of operator time. The payback period gets shorter at larger scales because of the economies of scale. A larger compressor is more efficient per ton of CO₂ than a smaller one, and the savings from avoiding massive CO₂ purchases accumulate much faster.

How much can a factory save by reusing CO₂ instead of buying it?

You get invoices for CO₂ deliveries every month. You pay for the product, the delivery fees, and the tank rental. You need to know exactly how much of that expense can be eliminated.

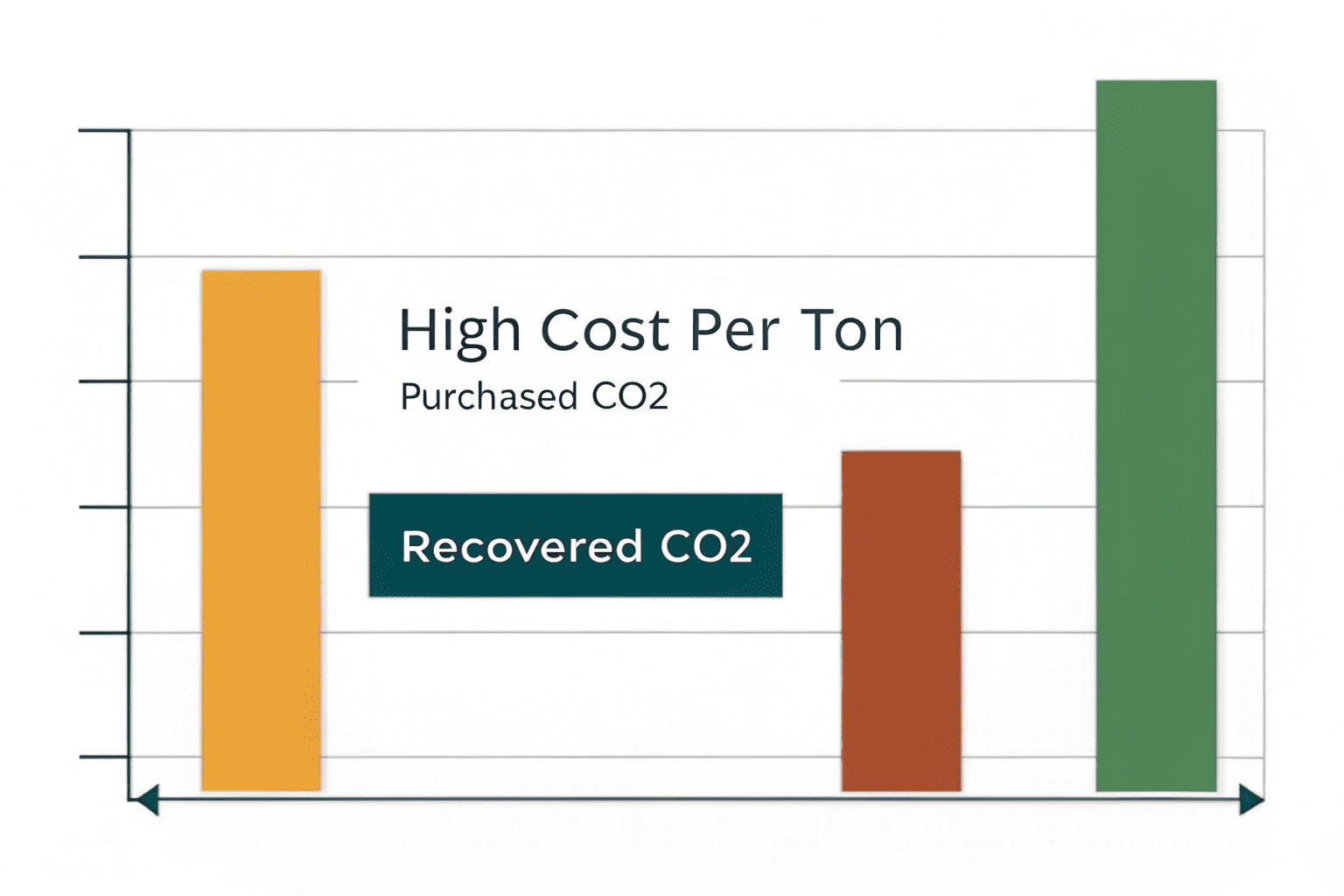

A factory can typically produce its own high-purity CO₂ for $40-$75 per ton. When compared to a purchase price of $150-$300+ per ton, the savings are substantial, often exceeding 70% of the previous CO₂ budget.

This is the calculation that gets every plant manager's attention. I recently worked with a mid-sized beverage company that was using 2,000 tons of CO₂ per year. They were paying an average of $220 per ton, including all fees. Their annual CO₂ expense was $440,000. We installed a recovery system, and their all-in cost to produce their own CO₂—covering electricity, maintenance, and labor—came out to about $60 per ton. Their new annual cost is just $120,000. That's a net saving of $320,000 every single year. These are the kinds of direct, impactful savings that show up clearly on a balance sheet. It's not a complex financial instrument; it's a simple, powerful reduction in a core operational expense.

The Cost of Production vs. Purchase

Let's look at the numbers for a hypothetical plant using 2,000 tons of CO₂ annually.

| Cost Item | Option 1: Purchase CO₂ | Option 2: Recover CO₂ with FTL Machine |

|---|---|---|

| Price per Ton | $220 | $0 (Self-produced) |

| Tank Rental / Delivery Fees | Included in price | $0 |

| Production Cost per Ton | N/A | $60 (Electricity & Maintenance) |

| Total Annual Cost | 2,000 tons * $220 = $440,000 | 2,000 tons * $60 = $120,000 |

| Annual Savings | - | $320,000 |

As you can see, the savings are dramatic. The cost of purchased liquid CO₂ is volatile and subject to supply chain disruptions and fuel surcharges. In contrast, the cost of producing your own CO₂ is stable and predictable, tied mainly to your local industrial electricity rate. This price stability gives you much greater control over your production budget.

Does CO₂ recovery reduce production and storage costs in the long run?

Your costs are not just about the price per ton. You also deal with logistical headaches, managing delivery schedules, and paying for large storage tanks just to ensure you never run out of CO₂.

Absolutely. CO₂ recovery significantly reduces long-term costs by creating supply chain independence. This eliminates delivery fees, tank rental costs, and the risk of production shutdowns due to supplier shortages or price spikes.

I talk to engineers like Jacky all the time, and their concerns go beyond the direct cost. They worry about supply chain reliability. What happens if a delivery is late? Or if the supplier suddenly raises prices by 30%? A production line can be shut down for want of a basic ingredient like CO₂. By installing a recovery plant, you take control of one of your key raw materials. You are no longer at the mercy of the market. You produce what you need, when you need it. This independence is a huge source of long-term value. Moreover, many companies pay thousands of dollars a month just to rent a large liquid CO₂ storage tank from their gas supplier. With your own production, you own the storage vessel, eliminating that perpetual rental fee forever.

Beyond the Price Tag: Long-Term Value

The financial benefits extend far beyond simple payback.

- Supply Chain Security: On-site production insulates your facility from external market volatility, transport strikes, and supplier issues. This ensures that a critical utility for your process is always available, preventing costly downtime.

- Elimination of Rental Fees: Most gas supply contracts include hefty monthly rental fees for the bulk storage tank. Owning your equipment eliminates this recurring cost, which can add up to tens of thousands of dollars per year.

- New Revenue Streams: If your process produces more CO₂ than you need, the excess can be sold to the local market. This can be a significant opportunity for beverage bottlers, food processors, or even greenhouses in your area, turning your recovery plant into a profit center.

Conclusion

CO₂ recovery is a smart financial decision. It cuts direct costs, offers a fast payback, and provides long-term value by securing your supply chain and reducing operational risks for years to come.

You may also be interested in:

Why is CO₂ recovery technology gaining popularity worldwide?

Why is CO₂ recovery technology gaining popularity worldwide? You see headlines about carbon capture everywhere. But you wonder if it's

Read more

How is a CO₂ recovery system designed to fit different industries?

How is a CO₂ recovery system designed to fit different industries? You're under pressure to implement a CO₂ recovery solution.

Read more

How energy-efficient are today’s CO₂ recovery technologies?

How energy-efficient are today’s CO₂ recovery technologies? You want to recover CO₂, but you fear that high electricity bills will

Read more