How safe and reliable are modern CO₂ recovery systems?

•

How safe and reliable are modern CO₂ recovery systems?

You're considering a CO₂ recovery system but worry about safety risks and costly downtime. A system failure could be catastrophic, creating both safety hazards and production losses.

Modern systems are incredibly safe, featuring automated shutdowns, redundant sensors, and pressure relief valves. They are also highly reliable, often achieving over 98% uptime with a proper preventative maintenance schedule, making them a dependable part of your production process.

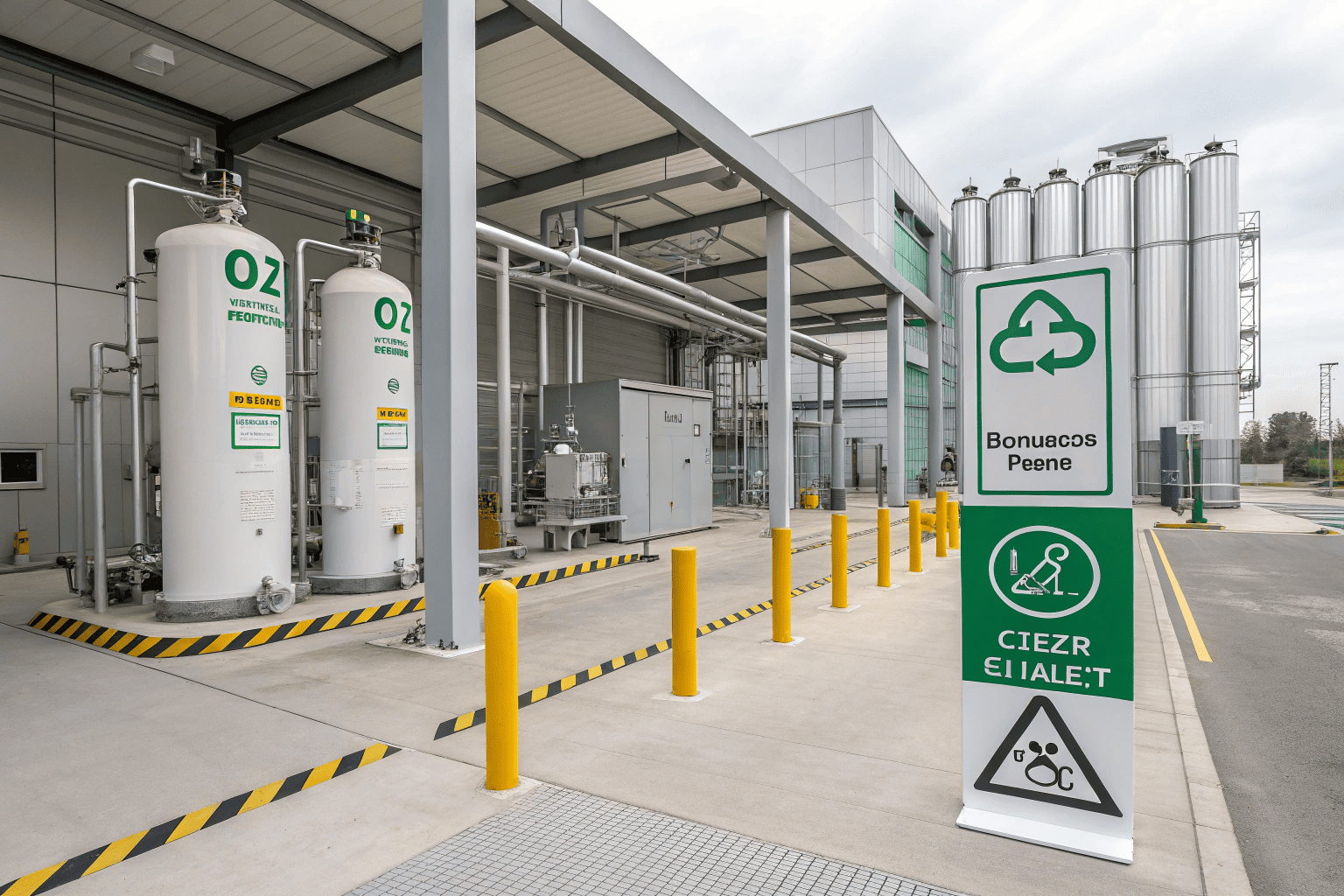

I understand the concern completely. As an engineer, no plant manager wants to introduce a new risk to their facility. Safety and reliability aren't just features for us at FTL Machine; they are fundamental to our entire design philosophy. We don't add them on at the end. We build them into the core of the system from the very first drawing. These plants are designed to be a safe, reliable part of your factory for decades. Let's break down exactly how we make that happen.

What safety measures are included in a CO₂ recovery plant?

High-pressure gas and cold liquid CO₂ are inherently hazardous materials. You need total confidence that the system has built-in protection against leaks, over-pressurization, and other potential dangers.

Standard safety features include pressure relief valves on all vessels, automated emergency shutdown (ESD) systems, and gas detection sensors. These layers work together to automatically and instantly secure the plant in case of any anomaly.

We design safety using a "defense-in-depth" strategy, which means there are multiple independent layers of protection. First, we have the passive hardware safeguards. Every tank and vessel is equipped with a mechanical pressure relief valve (PRV). This is a simple, foolproof device that will automatically vent pressure if it ever exceeds a safe limit, preventing a rupture. It's the ultimate line of defense and requires no power or computer control to work.

The next layer is the active, automated control system. The plant's PLC is a vigilant operator that never gets tired. It continuously monitors dozens of data points like pressure, temperature, and liquid levels. If any reading goes outside the safe operating window, the PLC will instantly trigger an automated shutdown. It safely closes valves, stops the compressor, and alerts operators. This automated response is faster and more reliable than a human could ever be. Finally, we install gas detectors in the equipment room. These sensors constantly monitor the air for high concentrations of CO₂, providing an early warning for any potential leaks to protect your personnel.

Layers of Safety Protection

| Safety Layer | Function | Example |

|---|---|---|

| Passive Mechanical | Provides foolproof protection against over-pressure | Pressure Relief Valves (PRVs) on all vessels |

| **Active Automated | ||

| ** | Continuously monitors and controls the process within safe limits | PLC with automated Emergency Shutdown (ESD) |

| Environmental Monitoring | Detects leaks into the plant environment to protect personnel | Room CO₂ gas detectors with alarms/ventilation |

How often should the system be inspected or serviced?

You need a system that doesn't demand constant attention. But neglecting maintenance leads to unexpected failures. Finding that balance is key to ensuring long-term reliability without excessive labor costs.

A structured maintenance schedule is key. This involves simple daily walk-arounds by operators, more detailed monthly inspections, and one comprehensive annual service by a qualified technician. Following this routine schedule ensures maximum uptime and system longevity.

A reliable machine is a well-maintained machine. The goal of our maintenance plan is to catch small issues before they become big problems. We provide every client with a detailed schedule tailored to their specific FTL Machine unit. It’s broken down into simple, manageable tasks. The most frequent are the daily checks. This is a quick 15-minute walk-around that your own operators can perform at the start of each shift. They check key pressure and temperature gauges, listen for any strange noises, and visually inspect for any leaks. It's a simple, effective first line of defense.

Monthly checks are more involved. This includes tasks like checking compressor oil levels, testing alarm functionality, and inspecting the filter media in the activated carbon towers. Then, once a year, we recommend a full service performed by one of our certified technicians. During this visit, we perform a deep inspection, calibrate sensors, replace wear-and-tear components like valve seats and gaskets, and provide a detailed report on the system's health. This preventative approach is the secret to the high reliability our clients experience.

Recommended Maintenance Schedule

| Frequency | Performed By | Key Tasks |

|---|---|---|

| Daily | Plant Operator | Visual inspection, check gauges, listen for anomalies. |

| Monthly | Plant Maintenance | Test alarms, check oil levels, inspect filters. |

| Annual | FTL Technician | Calibrate sensors, replace wear parts, full system health check. |

What are common issues operators should watch out for?

Every piece of industrial equipment has its common quirks. Knowing what to look out for in advance helps your team troubleshoot issues quickly, minimizing downtime and keeping production running smoothly.

Operators should mainly watch for gradual changes. This includes slowly decreasing CO₂ purity, a gradual drop in output, or minor leaks from valve packings or pipe flanges. Catching these subtle trends early prevents them from becoming larger problems.

Our systems are designed to be robust, but they are still complex machines operating 24/7. Catastrophic failures are extremely rare with proper maintenance. The issues your operators are most likely to encounter are small and gradual. The most common one is a slow decline in product purity. For example, if the purity drops from 99.98% to 99.92% over a few weeks, it's often a sign that the activated carbon in the purification filters is becoming saturated and needs to be replaced. Another common issue is a gradual drop in production capacity. If the plant was producing 10 tons per day and is now only making 9, it could point to a fouled heat exchanger or a compressor valve that isn't sealing perfectly.

These aren't emergencies, but they are indicators that maintenance is needed. We train operators to pay attention to these trends. We also teach them to look for small, physical signs during their daily walk-arounds. A minor "weep" from a valve packing or a small patch of frost on a pipe where there shouldn't be one can indicate a tiny gas leak. By logging and addressing these small observations early, your team can schedule maintenance proactively and keep the system running at peak performance.

Conclusion

Modern CO₂ recovery systems are exceptionally safe and reliable. With built-in safety layers and a straightforward maintenance plan, they are designed to be a dependable, worry-free asset for your factory.

You may also be interested in:

Why is CO₂ recovery technology gaining popularity worldwide?

Why is CO₂ recovery technology gaining popularity worldwide? You see headlines about carbon capture everywhere. But you wonder if it's

Read more

How is a CO₂ recovery system designed to fit different industries?

How is a CO₂ recovery system designed to fit different industries? You're under pressure to implement a CO₂ recovery solution.

Read more

How energy-efficient are today’s CO₂ recovery technologies?

How energy-efficient are today’s CO₂ recovery technologies? You want to recover CO₂, but you fear that high electricity bills will

Read more