How pure can recovered CO₂ gas be after processing?

•

How pure can recovered CO₂ gas be after processing?

You need high-purity CO₂ for your process, but you worry that recovered CO₂ won't be clean enough. Contaminants could spoil a product batch, leading to waste and financial loss.

Modern CO₂ recovery systems are engineered to produce gas with exceptional purity, typically ranging from 99.9% to 99.995%. This quality meets and often exceeds the stringent standards required for food, beverage, and medical applications, ensuring the final product is both safe and pure.

One of the first questions an engineer like Jacky always asks me is, "How can you guarantee the purity?" It's a valid and critical question. For a food or beverage company, the quality of their CO₂ is non-negotiable. A trace contaminant can alter the taste of a product and lead to a costly recall. I always explain that our job isn't just to capture CO₂; it's to refine it. We design our multi-stage purification systems specifically to target and remove the exact contaminants present in a client's unique gas stream. Let's look at how we achieve this.

What factors affect the purity of recovered CO₂?

Your raw source gas is a complex mixture, full of different compounds. You know that these impurities must be removed, but it seems like a very difficult technical challenge.

The primary factors are the composition of the source gas and the sophistication of the purification technology. A gas stream from fermentation is naturally cleaner than flue gas, which contains sulfur and nitrogen oxides that require more advanced filtration stages.

The source of the CO₂ is the single biggest variable we have to consider. Every project starts with a detailed analysis of the client's raw gas stream. We can't apply a one-size-fits-all solution, because the challenges are completely different. For example, the CO₂ coming off a brewery's fermentation tank is already very pure. It mostly contains water vapor and some volatile organic compounds (VOCs) that affect taste and smell. In contrast, the flue gas from a natural gas boiler is much more complex. It has a low CO₂ concentration and is mixed with nitrogen, oxygen, and problematic contaminants like nitrogen oxides (NOx) and sulfur oxides (SOx). Our job as equipment designers is to create the perfect sequence of purification steps to handle that specific "recipe" of contaminants.

The Source Gas Matters Most

The purification train must be designed to handle the specific contaminants present in the raw gas.

| Gas Source | Typical CO₂ % | Key Contaminants to Remove | Purification Challenge |

|---|---|---|---|

| Fermentation | >99% | Water, Ethanol, Acetaldehyde, VOCs | Low |

| Biogas Upgrading | 40-60% | Methane (CH₄), Hydrogen Sulfide (H₂S), Water | Moderate |

| Flue Gas | 4-15% | Nitrogen (N₂), Oxygen (O₂), NOx, SOx, Particulates | High |

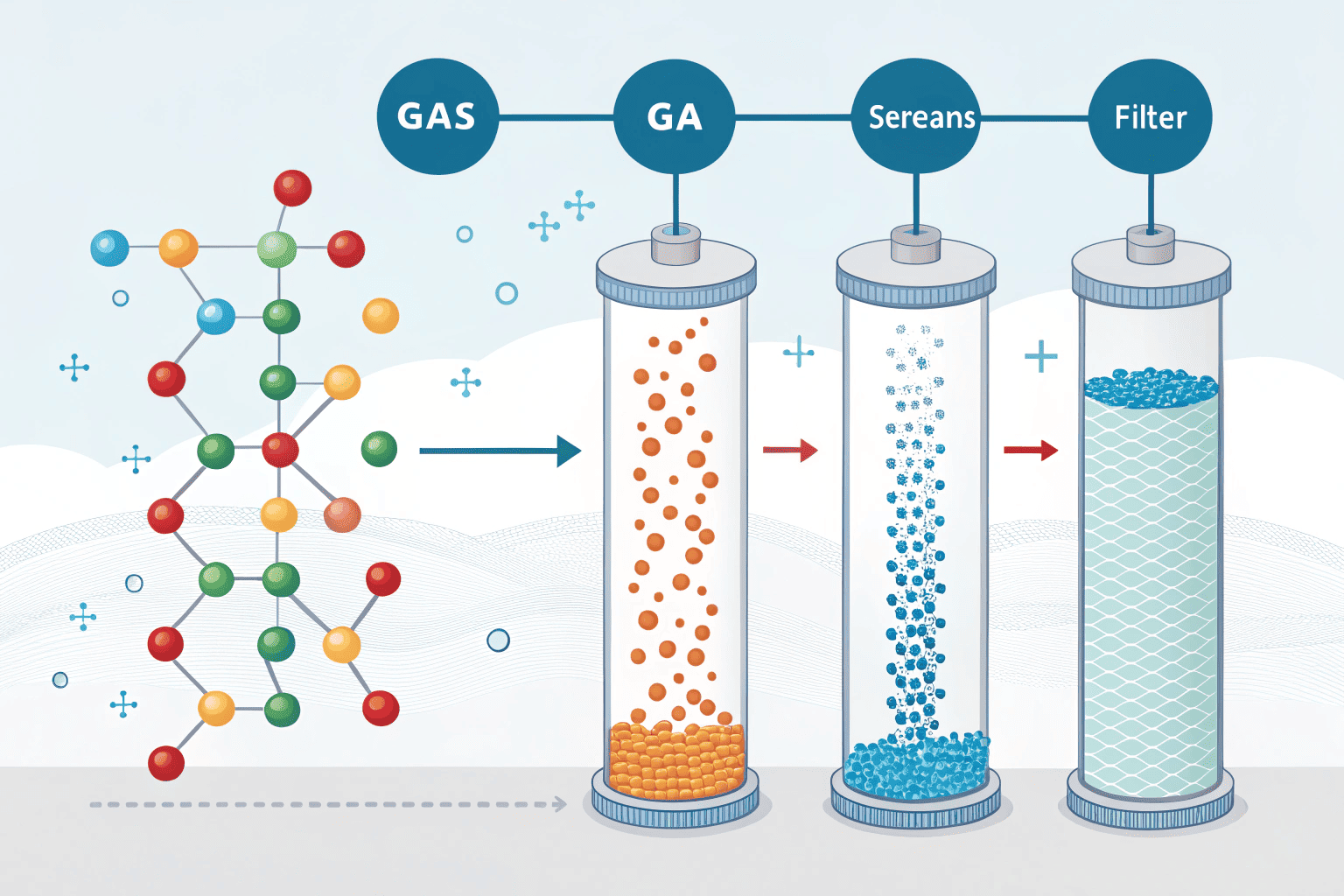

An FTL Machine system uses a a series of steps to address this. We use water scrubbers and coalescing filters to remove moisture and particulates. We then use activated carbon beds, which act like a sponge to absorb VOCs and other organic compounds. For sources like biogas, we add a special stage, like a permanganate scrubber, to specifically target and remove sulfur compounds that can cause foul odors. The final step is often liquefaction and distillation, which separates the pure liquid CO₂ from any remaining non-condensable gases like oxygen and nitrogen, ensuring the final product meets the highest standards.

How is CO₂ purity tested and monitored in recovery plants?

You cannot just trust that your gas is pure enough for production. A single bad batch could ruin your product reputation and lead to a massive recall, so you need proof and constant verification.

Purity is continuously checked with in-line gas analyzers that provide real-time data. This is supplemented by periodic, detailed batch testing using a gas chromatograph (GC) to detect trace impurities down to the parts-per-million level, ensuring consistent quality.

When you are making a food product, you don't guess about quality; you measure it. The same principle applies to the CO₂ we produce. Our systems are built with a two-level quality assurance process to provide complete peace of mind. The first level is constant, automated monitoring. Think of this as the system's vital signs monitor. We install in-line sensors, typically Non-Dispersive Infrared (NDIR) analyzers, right in the process pipe. These sensors measure the CO₂ concentration every second. If the purity drops below a pre-set level, say 99.9%, an alarm is triggered, and a diversion valve automatically vents the off-spec gas so it never reaches the storage tank. This provides a robust, real-time safety net for the entire operation.

A Two-Fold Approach: Real-Time and In-Depth

Combining continuous monitoring with periodic deep analysis provides a comprehensive quality guarantee.

- Continuous In-Line Monitoring: This is the first line of defense. NDIR sensors are installed at the outlet of the purification system. They provide a constant stream of data to the main PLC controller. This ensures that any major process upset is caught instantly, protecting the integrity of the CO₂ stored in the main tank.

- Gas Chromatography (GC) Analysis: This is the second, more detailed level of verification. At regular intervals, a sample of the final liquid CO₂ product is taken and analyzed in a lab using a gas chromatograph. A GC is an incredibly powerful instrument that separates the sample into its individual components. It can detect and quantify trace impurities like benzene or sulfur compounds down to parts per million (ppm), providing the ultimate proof that the product meets demanding food-grade specifications.

What purity levels are required for food and beverage applications?

Your company operates under strict food safety regulations. Using CO₂ that is not certified as food-grade is not an option, as it introduces risks of off-flavors, contamination, and regulatory non-compliance.

Food and beverage applications demand a minimum purity of 99.9% CO₂. Critically, the gas must also meet strict limits on specific trace contaminants defined by the International Society of Beverage Technologists (ISBT), which governs product safety and quality.

This is where the details really matter. When we talk about "food-grade" CO₂, achieving a high percentage like 99.9% is only the first step. The real challenge, and the most important aspect for consumer safety, lies in controlling the remaining 0.1%. Organizations like the ISBT have created very specific guidelines that set maximum allowable limits for dozens of different potential contaminants. These rules exist because even tiny amounts of certain substances can affect the taste, smell, and safety of the final product. For example, a few parts per million of sulfur compounds can give a soda a faint "rotten egg" smell. Traces of acetaldehyde can make a beer taste like green apples. Our entire purification process is designed around meeting and exceeding these specific ISBT targets.

Beyond the Nines: It's About the Contaminants

The quality of food-grade CO₂ is defined by the absence of specific trace impurities.

| Contaminant | ISBT Maximum Limit | Potential Impact on Beverage |

|---|---|---|

| Purity (CO₂) | > 99.9% vol | Ensures proper carbonation and product integrity |

| Acetaldehyde | < 0.2 ppm | Causes an "off" fruity or green apple taste |

| Benzene | < 20 ppb | A known carcinogen; regulated for consumer safety |

| Total Sulfur | < 0.1 ppm | Creates undesirable "rotten egg" or "garlic" smells |

Our commitment at FTL Machine is to provide a complete solution that delivers beverage-quality CO₂, guaranteed. We do this by tailoring the purification technology—the activated carbon filters, scrubbers, and final distillation column—to the specific contaminants in your source gas. This ensures that every ton of CO₂ you produce is not just pure, but also safe and free of any compounds that could compromise the quality of your brand.

Conclusion

Modern CO₂ recovery systems consistently deliver exceptional gas purity. Through tailored purification and rigorous, multi-level monitoring, we ensure the final product meets the strictest food-grade standards for any application.

You may also be interested in:

Why is CO₂ recovery technology gaining popularity worldwide?

Why is CO₂ recovery technology gaining popularity worldwide? You see headlines about carbon capture everywhere. But you wonder if it's

Read more

How is a CO₂ recovery system designed to fit different industries?

How is a CO₂ recovery system designed to fit different industries? You're under pressure to implement a CO₂ recovery solution.

Read more

How energy-efficient are today’s CO₂ recovery technologies?

How energy-efficient are today’s CO₂ recovery technologies? You want to recover CO₂, but you fear that high electricity bills will

Read more