How much does carbon capture cost?

•

How much does carbon capture cost?

Worried about the huge price tag on carbon capture systems? This uncertainty often stops progress, making it hard to decide if the investment is right for your facility.

The cost of carbon capture varies widely, from $50 to over $600 per ton of CO2. The price depends heavily on the source of the CO2, the technology used, the scale of the operation, and the final purity level required for reuse.

As an engineer who designs these systems, I get this question all the time. The final cost isn't just a number on an invoice; it's a reflection of your specific operational needs. But beyond the initial investment, the real question is whether it makes financial sense. Let's explore the factors that truly matter.

Is carbon capture profitable?

Investing in new technology feels like a huge risk. You can't afford a system that only adds to your expenses without providing a clear return on that investment.

Yes, carbon capture can be very profitable. The key is creating value from the captured CO2. Industries like brewing and chemical manufacturing can reuse their own CO2, generating significant savings and even creating new revenue streams by selling the surplus.

I've seen firsthand how a well-designed system turns a waste product into a valuable asset. The initial cost is an investment, not just an expense. The profitability comes from shifting your mindset from CO2 disposal to CO2 utilization. Let's look at how this works in practice.

From Cost Center to Profit Center

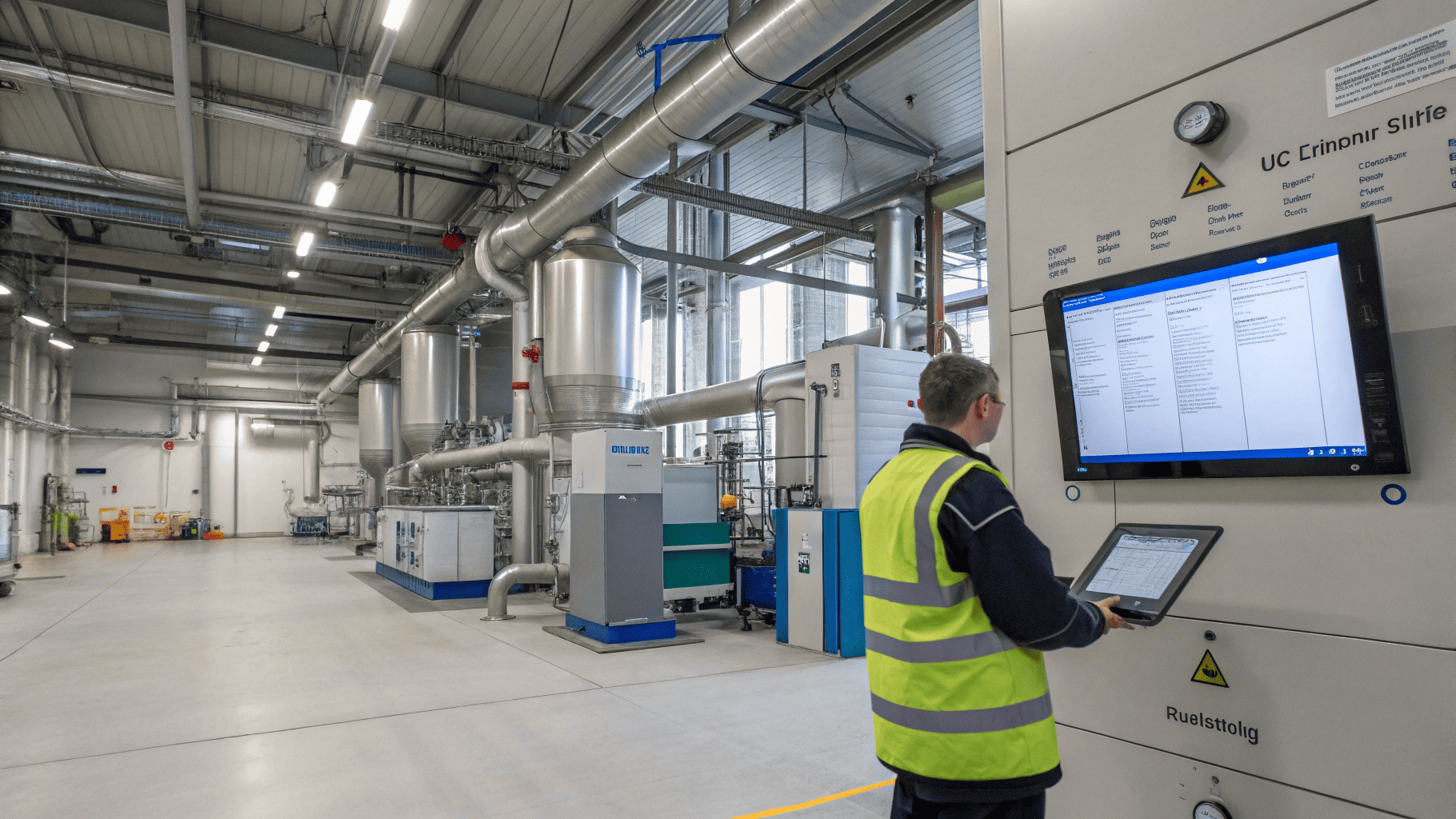

The most successful projects I've worked on involve creating a closed-loop system. A brewery, for example, produces high-purity CO2 during fermentation. Instead of venting this gas and then buying CO2 for carbonation, they capture and reuse it. This immediately cuts purchasing costs. In the chemical industry, plants can capture CO2 and sell it for food preservation or other industrial uses. Government incentives and carbon taxes can further improve the financial picture, making the system a clear profit generator rather than just an environmental compliance tool.

| Financial Impact | Without CO2 Capture | With CO2 Capture System |

|---|---|---|

| CO2 Supply | Purchase from external supplier (Cost) | Reuse captured CO2 (Savings) |

| Emissions | Pay carbon taxes or penalties (Cost) | Lower taxes, earn credits (Savings) |

| Waste Stream | Venting gas (Wasted potential) | Sell surplus CO2 (Revenue) |

What is the problem with carbon capture?

You have probably heard about the downsides of carbon capture. These concerns can make you hesitant to adopt the technology, especially when you hear about high energy use and costs.

The main challenges with carbon capture are the high initial investment and the energy required to run the system, often called the "energy penalty." Additionally, long-term storage of CO2 presents a complex problem, which is why onsite utilization is often a better solution.

It’s true, these systems are not perfect. As an engineer, my job is to be honest about the challenges and design solutions that overcome them. The "energy penalty" is a real thing; it takes energy to separate CO2 from other gases. However, technology is constantly improving to reduce this.

Overcoming the Hurdles

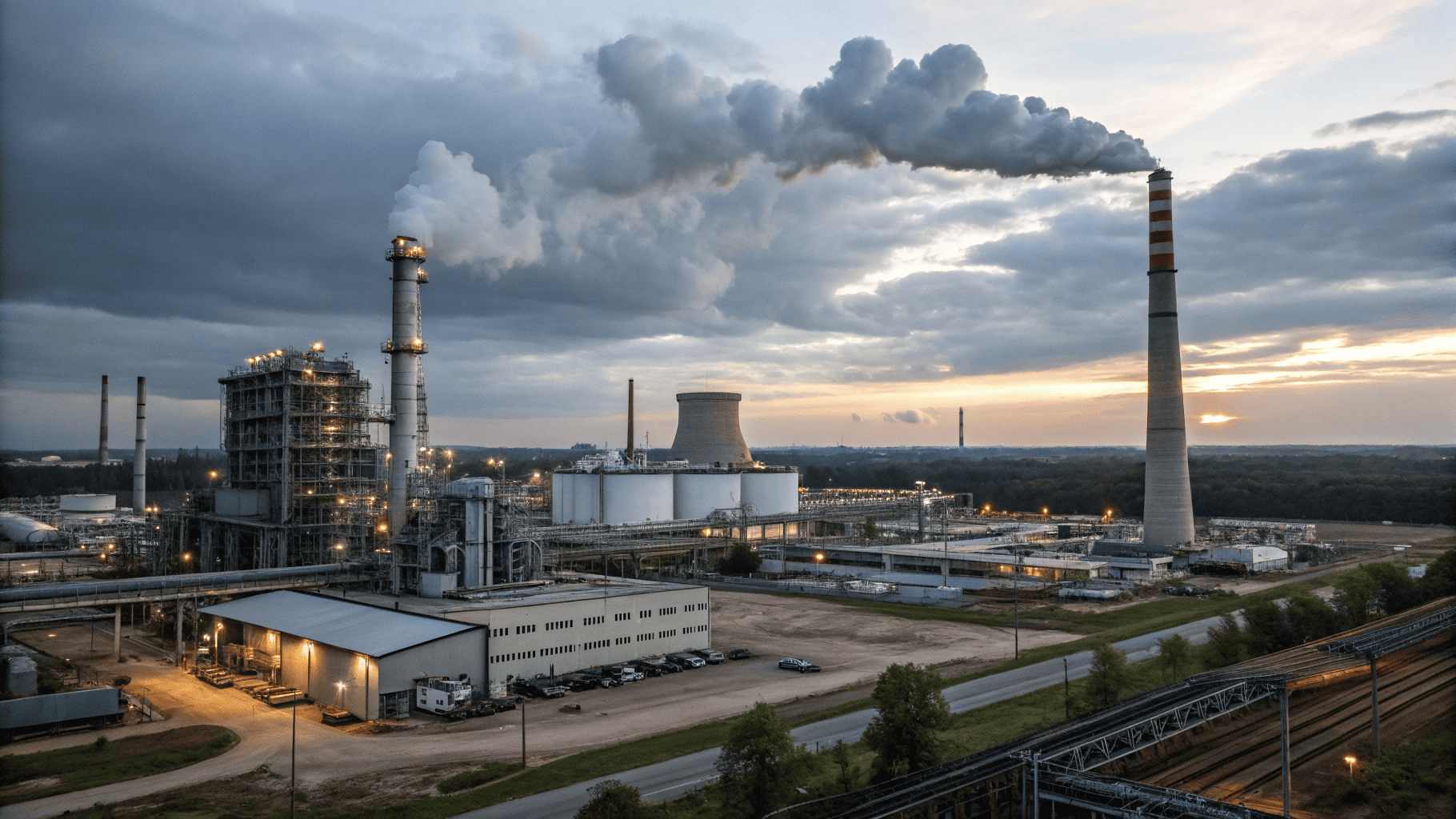

The key to a successful project is choosing the right technology for your specific gas stream. Capturing CO2 from a pure source, like a brewery's fermentation tank, requires far less energy than capturing it from a dilute flue gas stream from a power plant. This is a critical distinction. At FTL Machine, our focus is on these high-concentration sources. By targeting these applications, we design systems that are much more energy-efficient and cost-effective. The storage issue also becomes irrelevant when the captured CO2 is immediately purified and reused on-site. This approach solves both the energy and storage problems at once.

Who has the best carbon capture technology?

Choosing a technology partner is difficult. You need a reliable system from a company you can trust, but the market is full of different options and bold claims.

There is no single "best" technology for all situations. The ideal solution depends on your specific industrial process. Companies that specialize in applications like breweries or chemical plants often provide the most efficient and cost-effective systems for those needs.

When I talk to clients, I always steer the conversation away from finding a "best" universal technology. Instead, we focus on finding the best technology for them. This means matching the system's capabilities directly to their operational needs and CO2 source. A large-scale system designed for a power plant is a poor fit for a mid-sized brewery, and vice versa.

Finding the Right Fit

The leading technology providers are those who understand this. They have deep expertise in specific industries. For example, our work at FTL Machine is highly focused. We build systems for industries that produce high-purity CO2, like brewing and chemical production. This specialization allows us to optimize every component for that environment, maximizing efficiency and minimizing operational costs. When choosing a partner, look for this kind of specialized experience. A company that understands your industry’s unique challenges will always deliver a better, more reliable solution.

Conclusion

Carbon capture costs are manageable and often profitable. By choosing the right technology for your specific needs, you can turn an environmental liability into a valuable operational asset.

You may also be interested in:

Why is CO₂ recovery technology gaining popularity worldwide?

Why is CO₂ recovery technology gaining popularity worldwide? You see headlines about carbon capture everywhere. But you wonder if it's

Read more

How is a CO₂ recovery system designed to fit different industries?

How is a CO₂ recovery system designed to fit different industries? You're under pressure to implement a CO₂ recovery solution.

Read more

How energy-efficient are today’s CO₂ recovery technologies?

How energy-efficient are today’s CO₂ recovery technologies? You want to recover CO₂, but you fear that high electricity bills will

Read more