How does CO₂ recovery support sustainability and carbon reduction goals?

•

How does CO₂ recovery support sustainability and carbon reduction goals?

Your company has set ambitious sustainability targets, but achieving them feels abstract and overwhelming. The pressure from regulators and consumers is mounting, and you need a concrete, practical solution to reduce emissions.

CO₂ recovery provides a direct path to sustainability by capturing carbon emissions at the source, preventing their release into the atmosphere. This captured CO₂ can then be reused in a circular model or permanently stored, significantly lowering a company’s carbon footprint and demonstrating tangible environmental action.

I've been in this industry for a long time, and I've seen the conversation around emissions change dramatically. It used to be about grudging compliance and the cost of regulations. Now, the engineers and managers I talk to are genuinely looking for ways to build more sustainable businesses. They see the writing on the wall. They know that reducing their carbon footprint is not just good for the planet; it's essential for long-term survival and profitability. The question is no longer "Why should we do this?" but "What's the most effective way to start?"

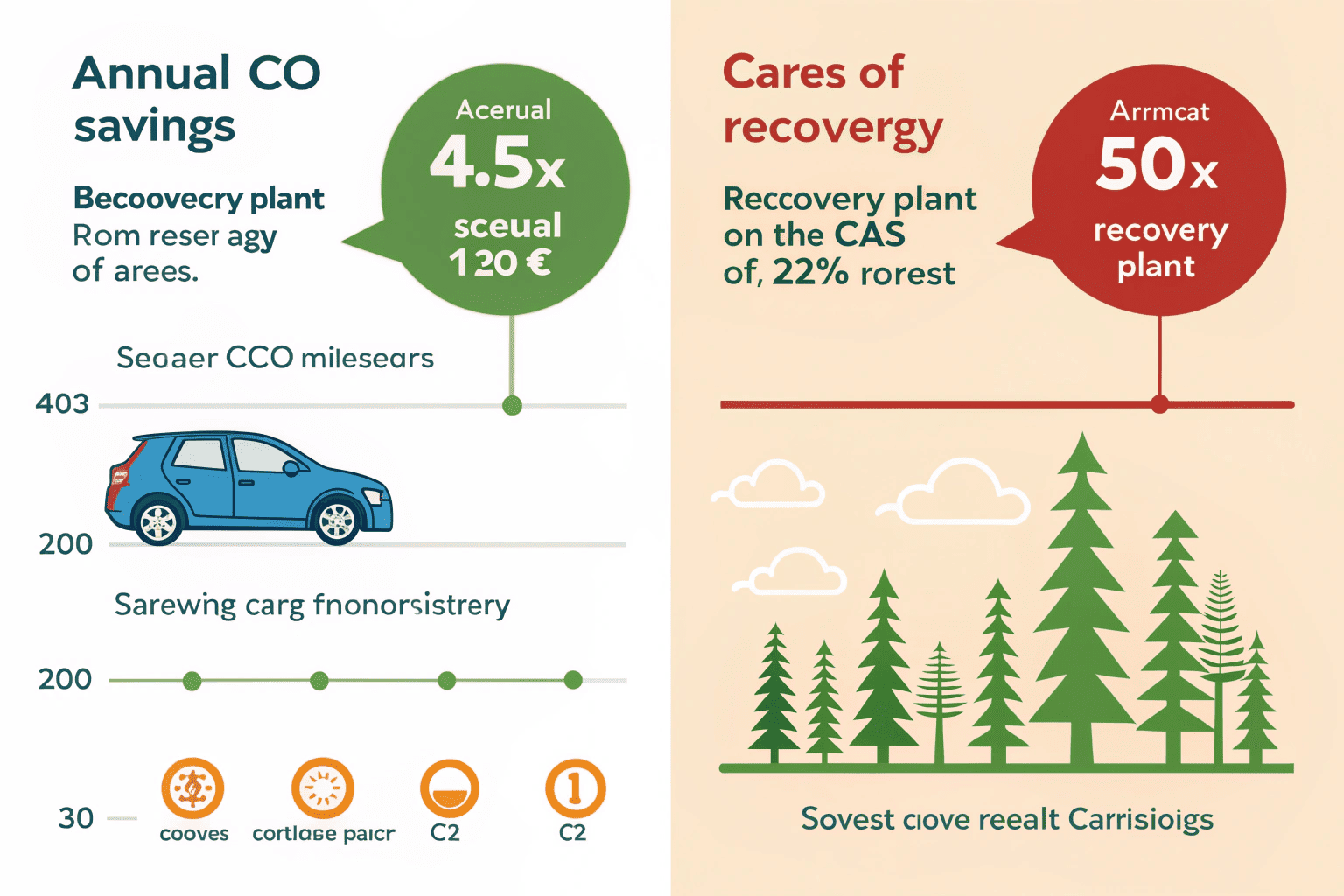

How much CO₂ can be saved by installing a recovery plant?

You know your plant emits CO₂, but the volume is just an abstract number on a report. It's hard to justify a major project without knowing the tangible impact it will have.

The amount saved depends on the gas flow rate and CO₂ concentration. A mid-sized brewery can recover 1,000 to 5,000 tons per year, while a large ammonia or ethanol plant could capture over 100,000 tons annually—equivalent to taking tens of thousands of cars off the road.

One of the first things I do with a potential client is a feasibility study. We don't talk in vague terms; we calculate the real numbers. Seeing the sheer volume of CO₂ they are venting every single day—often hundreds of tons—is usually an eye-opening moment. When an engineer like Jacky sees that their plant is emitting the equivalent of 10,000 cars' worth of CO₂ a year, and that we can capture nearly all of it, the project suddenly moves from a "nice-to-have" to a "must-do." Making the abstract tangible is what turns sustainability goals into engineering projects.

Quantifying Your Recovery Potential

The potential for CO₂ recovery varies significantly by industry. We determine this by analyzing the specific parameters of your gas stream.

| Industry | Gas Source | Typical CO₂ Concentration | Potential Annual Recovery |

|---|---|---|---|

| Brewery | Fermentation Off-Gas | >99% | 1,000 - 5,000 tons |

| Ethanol Plant | Fermentation Off-Gas | >99% | 100,000 - 250,000 tons |

| Ammonia Plant | Syngas Production | ~15-40% | 50,000 - 500,000+ tons |

| Natural Gas Plant | Flue Gas from Turbines | ~4-10% | 100,000 - 1,000,000+ tons |

To put this in perspective, capturing 100,000 tons of CO₂ is like planting 1.5 million trees and letting them grow for 10 years. Our process at FTL Machine starts with a detailed analysis of your flow rate, gas composition, and pressure. With this data, we can design a system to capture over 99% of the CO₂ in the target stream and give you a precise calculation of your annual carbon reduction.

What role does CO₂ reuse play in achieving net-zero emissions?

Net-zero emissions can feel like an impossible target for heavy industry. Simply capturing CO₂ is a good start, but if it eventually gets released, have you really solved the problem?

CO₂ reuse, or utilization, plays a vital role by creating a circular carbon economy. Using captured CO₂ as a resource displaces the need for fossil-fuel-derived CO₂, effectively locking it into products and preventing new emissions from being created.

The ultimate goal of net-zero isn't just to stop emitting; it's to create a balance where any remaining emissions are offset. CO₂ reuse is a powerful tool to achieve this balance. When you capture CO₂ and use it to carbonate a beverage or make plastic, you are giving that carbon atom a job to do. Instead of being a pollutant in the atmosphere, it becomes a structural part of a new product. This is the core concept of Carbon Capture and Utilization (CCU). It's about shifting our mindset from treating CO₂ as a waste to be disposed of, to seeing it as a valuable and sustainable feedstock for the next generation of industrial products.

From Waste Stream to Value Chain

CCU is about displacing emissions. Every ton of reused CO₂ is a ton that doesn't need to be produced by burning more fossil fuels.

- Direct Displacement: When a brewery reuses its fermentation CO₂, it directly avoids purchasing CO₂ made from natural gas reforming. This has an immediate and measurable impact on emissions.

- Long-Term Sequestration: When captured CO₂ is used to create durable products, like concrete or building polymers, it is effectively mineralized and stored for centuries. The carbon is taken out of the atmospheric cycle for a very long time.

- Creating New Markets: Innovative companies are now using captured CO₂ to create carbon-negative products, from sustainable aviation fuels (e-fuels) to even carbon-based diamonds. These new value chains are built on the foundation of captured CO₂.

How can companies use recovered CO₂ in new green products?

You have successfully captured your CO₂, turning an emission into a pure, liquid product. The next question is, what can you do with it to create even more value and enhance your green credentials?

Companies are using recovered CO₂ to create innovative green products like carbon-cured concrete, biodegradable plastics (polycarbonates), and synthetic fuels. These applications turn a captured liability into a marketable, sustainable asset, opening up entirely new revenue streams.

This is where the future of the industry is headed. For years, the primary uses for recovered CO₂ were well-established: carbonation, food freezing, and enhanced oil recovery. But now, I'm working with pioneers who are treating CO₂ as a C1 building block for a new generation of materials and chemicals. It’s a complete paradigm shift. Instead of just avoiding a penalty, these companies are using a "waste" product to create premium, eco-friendly goods that command higher prices in the marketplace.

The Emerging CO₂ Marketplace

Innovation is turning captured carbon into the foundation of a new green economy.

- Green Building Materials: Injecting CO₂ into a concrete mix triggers a chemical reaction that mineralizes the CO₂, permanently storing it and increasing the concrete's strength. This process can make concrete a carbon sink rather than a source.

- Sustainable Fuels (E-Fuels): By combining captured CO₂ with green hydrogen (produced using renewable electricity), companies can synthesize liquid fuels like methanol or jet fuel. These fuels are carbon-neutral, as the CO₂ released when they are burned is the same CO₂ that was captured to make them.

- Bioplastics and Polymers: Researchers are developing new methods to use CO₂ as a co-monomer in the production of polymers for plastics. This reduces the reliance on petrochemical feedstocks and locks carbon into the final product.

Conclusion

CO₂ recovery is a direct, measurable step towards sustainability. It reduces emissions, enables a circular economy through reuse, and paves the way for innovative green products that define the future of industry.

You may also be interested in:

Why is CO₂ recovery technology gaining popularity worldwide?

Why is CO₂ recovery technology gaining popularity worldwide? You see headlines about carbon capture everywhere. But you wonder if it's

Read more

How is a CO₂ recovery system designed to fit different industries?

How is a CO₂ recovery system designed to fit different industries? You're under pressure to implement a CO₂ recovery solution.

Read more

How energy-efficient are today’s CO₂ recovery technologies?

How energy-efficient are today’s CO₂ recovery technologies? You want to recover CO₂, but you fear that high electricity bills will

Read more