Project for recovering CO₂ from tail gas of ethylene cracking unit

Core Performance Metrics

Product grade

product grade

Reducing carbon footprint while creating value

Purity of CO₂ recovery

99.97%

Exceeding food-grade quality standards

Energy recovery rate

85%

Compared to conventional systems

Annual recycling volume

150000 tons

Fast return on investment

Client Name

LG Chem of South Korea

Project Location

Yeosu Petrochemical Complex, South Korea

Commissioning Date

September 2022

Equipment Model

FTR-CHEM300

Special requirements of the chemical industry

Industry characteristics

-

The composition of cracking gas is complex.

-

"Requirements for High-Pressure Working Conditions"

-

"Food-grade CO₂ required"

A real scene picture of the chemical plant area

The existing fermentation facility with outdated CO₂ emission systems requiring urgent environmental and efficiency upgrades.

Our Solution

Close-up series pictures of the equipment

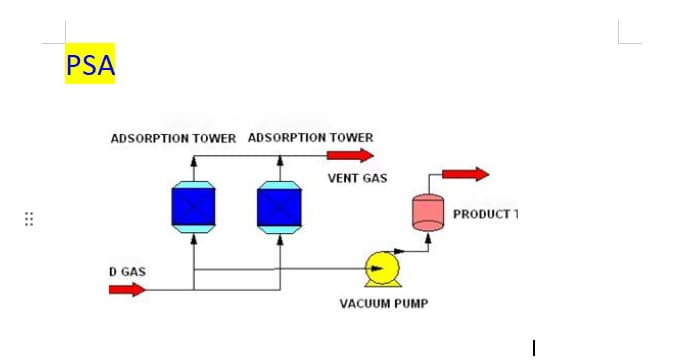

"PSA Pretreatment Unit" ── "Low-Temperature Distillation Column ── "Catalytic Oxidation Dehydrocarbon" ──"Liquid storage system.

Process flow chart

"PSA Pretreatment Unit" ── "Low-Temperature Distillation Column ── "Catalytic Oxidation Dehydrocarbon" ──"Liquid storage system.

Technical breakthrough

──"Trace Sulfur Removal Technology" ──"Three-stage Compression System" ── "APC Advanced Control"

Project Results

Economic Benefits Analysis

| Benefit Category | Value | Impact |

|---|---|---|

| CO₂ Product Value | $120/ton | Additional revenue stream |

| Steam Recovery | $2M/year | Waste heat utilization |

| Payback Period | 3.2 years | Fast ROI |

| Carbon Credits | $450k/year | Environmental compliance |

"This CO₂ recovery system has revolutionized our petrochemical operations. By converting our ethylene cracking byproducts into high-purity CO₂, we've achieved both environmental compliance and created a new profit center. The system's ability to handle complex gas compositions while delivering 99.97% purity has surpassed our most stringent quality requirements."

Nguyen Van Minh

Operations Director, Vietnam Beverages Ltd.

Equipment Technical Parameters

FTR-CHEM300 Technical Specifications

| Parameter | Specification | Technical Notes |

|---|---|---|

| Gas Processing Capacity | 15,000 Nm³/h | For ethylene cracking flue gas |

| Operating Pressure | 2.5-3.8 MPa | High-pressure process optimized |

| Hydrocarbon Content | <5 ppm | Advanced catalytic oxidation |

| Liquefaction Capacity | 20 t/h | High-efficiency cryogenic system |

| System Availability | ≥96% | Redundant design for reliability |

| Energy Consumption | 1.05 kWh/kgCO₂ | With heat recovery system |