Cement Industry Solution

Core Performance Metrics

Daily Flue Gas Processed

800,000 Nm³

Cement kiln exhaust treatment capacity

CO₂ Capture Rate

90%

From industrial flue gases

Mineralization Rate

65%

CO₂ converted to stable minerals

Annual CO₂ Reduction

200,000 tons

Equivalent to planting 3.3M trees

Exclusive solutions for the cement industry

Our comprehensive solution captures, purifies, and recycles CO₂ from the fermentation process, creating a closed-loop system that minimizes emissions while producing food-grade CO₂.

Client Name

Thailand SCG Cement Group

Project Location

Ho Chi Minh City, Vietnam

Commissioning Date

March 2022

Equipment Model

FTL-3000

Project Background & Challenges

Client Pain Points

-

The CO₂ concentration in the kiln tail gas is high (18-22%).

-

High dust content

-

The temperature of the exhaust gas fluctuates sharply

customer requirement

Meet Thailand's carbon tax policy │ "CO₂ mineralized Building Materials │"Does not affect existing production"

Our Solution

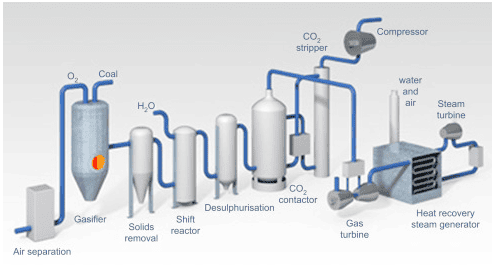

process flow diagram

High-temperature electrostatic precipitator pretreatment ── "Two-Stage Amine Absorption Tower── "Mineralization Reactor System ── "Calcium Carbonate Product Line

Blight spot technique

"Anti-dust clogging design" ----"Waste Heat Utilization System" ---- "Modular Quick Installation"

Project Results

Performance Improvements

| Key Performance Indicators | Value | Impact |

|---|---|---|

| Carbon Tax Savings | $2.8M/year | Regulatory compliance + revenue |

| Calcium Carbonate Self-sufficiency | 40% | Reduced raw material costs |

| System Energy Consumption | 11% of total capacity | Low operational burden |

"Integrating FTR-C800 into our cement production line was a game-changer. We now capture 90% of kiln emissions while producing high-purity CO₂ for commercial use. The system paid for itself in just 18 months through carbon credit sales and reduced raw material costs."

Equipment Technical Parameters

FTR-C800 Technical Specifications

| Parameter | Specification | Technical Notes |

|---|---|---|

| Processing Capacity | 30,000 tCO₂/year | Equivalent to 800,000 Nm³/day flue gas |

| Operating Temperature | 120-180℃ | Optimal for cement plant integration |

| Power Consumption | 1.2 kWh/kgCO₂ | Industry-leading efficiency |

| Dimensions (L×W×H) | 25m × 18m × 12m | Modular design for easy installation |

| System Availability | ≥95% | Proven reliability in harsh conditions |

| Maintenance Cycle | 8,000 hours | Minimized downtime |